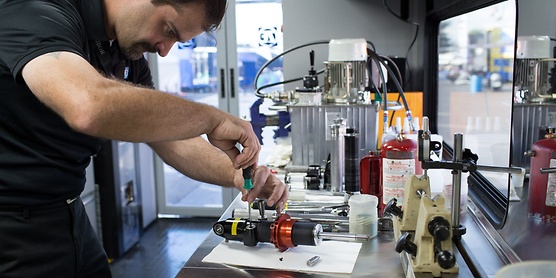

OE quality

SACHS products are manufactured from high-quality materials and reflect the state of the art. They stand for high performance and reliability. This is why numerous well-known automotive manufacturers equip their vehicles with SACHS products: Every year, more than 10 million new vehicles equipped with SACHS dampers and shock absorbers roll off the production line.

Moreover, SACHS offers high-quality clutches for original equipment manufacturers and the spare-parts market.

SACHS history

How everything started

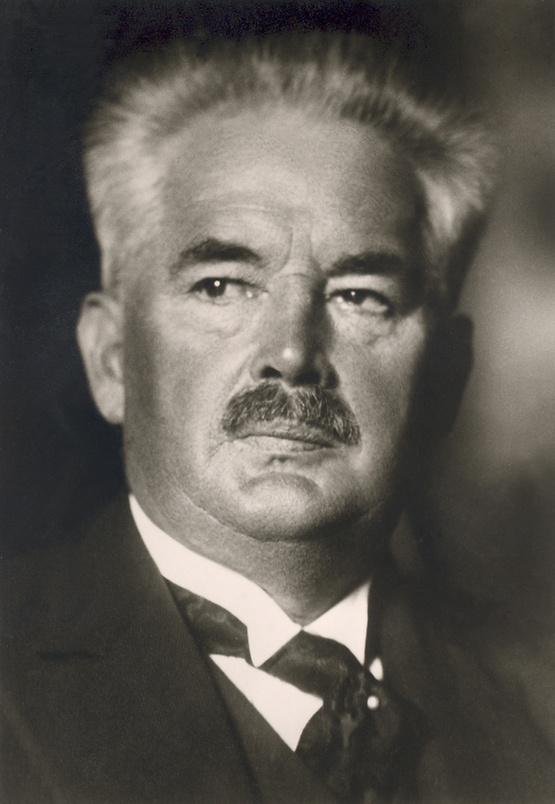

The history of the SACHS brand starts in 1894 when the toolmaker and name-giver Ernst Sachs filed his first bicycle wheel hub patent application. One year later, he founded the "Schweinfurter Präzisionskugellager-Werke Fichtel & Sachs" (precision ball bearing production plant) together with Karl Fichtel, a merchant and financier.

Then, as today, the stated philosophy was to secure a clear technological edge over competitors, both in terms of product quality and innovation, and in terms of customer service.

Born in Konstanz in 1867, Ernst Sachs had shown an evident interest in technical mechanisms and great sporting ambitions from an early age. As an amateur driver, he celebrated his first successes in bicycle racing, but found that the bicycle's bearings did not run smoothly enough. His striving for perfection consequentially led to the development of the first precision hub. After moving to Schweinfurt, he met the accomplished merchant Karl Fichtel.

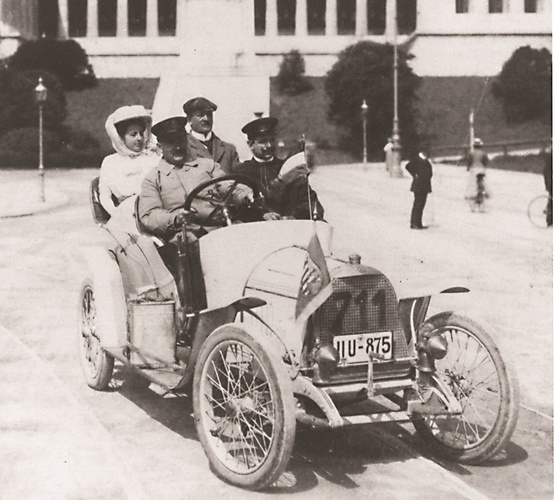

The patenting of Sachs' invention led to the joint decision to found the "Schweinfurter Präzisions-Kugellager-Werke Fichtel & Sachs" on August 1, 1895, for the production of ball bearings and wheel hubs for bicycles. The market launch of the Torpedo free-wheeling hub for bicycles in 1903 marked the start of the company's rise. The breakthrough of the bicycle as a means of mass transportation resulted in rapid growth; in 1905, Fichtel & Sachs already had 900 employees.

When Commercial Director Karl Fichtel died early and unexpectedly in 1911, Ernst Sachs took over the sole management of the company that had grown to around 2,600 employees. Against the backdrop of the economic crisis, Sachs transformed the company into a corporation in 1923 before selling the ball bearing division in 1929 and focusing on the production of vehicle engines, clutches, and shocks and dampers. One of his last developments was a light two-stroke engine that was installed in almost all small motorized bicycles of leading manufacturers as of 1932. The inventor died in the same year and his son Willy took over the company.In 1945, after the turmoil of the war, 67 percent of the plant facilities in Schweinfurt were destroyed; in spite of this, production was restarted at the end of the year. New sales success was achieved at the beginning of the fifties with the legendary "Sachser," a 50 cc engine with a two-speed transmission for mopeds.

With the market success of other innovative developments, the parent plant in Schweinfurt had to be doubled in size in 1969. In addition, several companies were acquired and the corporation took the first step into North America, before Mannesmann AG acquired the majority of shares in 1987. The company's internationalization continued and in 1995 Fichtel & Sachs was represented around the globe, with 38 production and sales companies. Renamed ZF Sachs AG, the company became part of the ZF Group in 2001 and was merged into ZF Friedrichshafen AG in 2011. Today, products of the SACHS brand are successfully sold internationally by ZF Aftermarket, together with the LEMFÖRDER, TRW, WABCO and BOGE brands.

The eventful and successful history of the SACHS brand and family has been on display in an exhibition on the ZF plant grounds in Schweinfurt since May 2015. On 850 square meters in a reconstructed former manufacturing shop, visitors will not only find displays on the company history, but also a great number of exhibits. In order to make history tangible and provide visitors with a first-hand experience, the exhibition is divided into four sections: The company history from 1895 to 2011, the technological highlights and milestones, the commitment to motorsports up to Formula 1, and an outlook on current developments in e-mobility and lightweight design.

Product range SACHS

Quality across Borders

SACHS offers products for various fields of application that cover almost all vehicle types. This applies to the European as well as the Asian vehicle market. Today, in Europe alone, the SACHS spare-parts portfolio includes shocks and dampers for more than 38 million Asian vehicles of various manufacturers. This is reassuring for trade partners, workshops and vehicle owners who can count on SACHS quality for a wide range of models.

Motorsports Expertise

With SACHS, ZF is actively involved in professional motorsports. As supplier for various teams, SACHS has already been involved in more than 100 wins and has gained wide experience in motorsports. This experience is used in the development and manufacturing of SACHS products. As a result, each SACHS product contains a good share of motorsports expertise.

Further Services for you

Quality Certification according to regulation (EU) No. 461/2010

Products sold by ZF Aftermarket under the SACHS brand are spare parts within the meaning of Article 1 Figure (1) h) of Regulation (EU) No. 461/2010 dated May 27, 2010, and meet the criteria of Figures (19) and/or (20) of the supplementary guidelines on vertical restraints in agreements concerning the sale and servicing of automobiles and the sale of automobile replacement parts to the aforementioned regulation.