ZF Aftermarket product portfolio

Every brake actuation component is matched to OE standards, and our extensive range has exceptional coverage of the European vehicle parc. No surprise to you, we hope – which means no nasty surprises for your customers, either.

Even the finest braking system will only perform at its full potential with the best components and accessories, such as master cylinders, brake hoses and brake fluid. TRW True Originals are your first choice for stopping power and stability when supplying or fitting brake actuation parts.

The TRW product portfolio

A range like no other, from brake boosters to brake hoses and master cylinders

Because we design braking systems for global vehicle manufacturers, we understand better than anyone exactly what’s needed to keep them running smoothly, safely and powerfully. This also means that we’re at the forefront of braking technology developments, keeping you and your customers up to date with the latest innovations featuring as additions to the range.

From brake master cylinders to ABS sensors, every item in the TRW Originals brake actuation range is of exceptionally high-quality design and manufacture, down to the finest detail. All TRW Originals products meet or exceed original equipment (OE) standards thanks to our precision engineering and the tough testing, and overall, the range covers a vast number of vehicle models.

Put TRW True Originals to the test - we always do

We have our own in-house dynamometer and endurance testing facilities (we are one of the very few aftermarket manufacturers that does). This means that we can carry out quality and process control for ourselves, without relying on external third-party test facilities.

See for yourself: discover more about TRW brake actuation systems, including brake fluid, brake cleaner, brake master cylinders, brake hoses, brake boosters, handbrake and clutch cables, ABS sensors and clutch cylinders by taking a look at our online catalogue.

ABS sensors

TRW offers a full range of original equipment (OE) standard ABS Sensors for all of the major manufacturers in Europe and Asia, giving you a fantastic opportunity to improve safety for almost any customer.

The benefits of choosing TRW for ABS Sensors include:

- Huge selection of designs to meet specific car requirements

- More than 540 part numbers

- Premium materials including shrink-wrapped signal and power cables

- All parts tested to the extreme to guarantee exceptional performance

We can guarantee functional ABS Sensor stability and reliability in all conditions, from -40oC up to +150 oC. That’s because we thoroughly test and examine all of our ABS Sensors to the extreme. Our testing processes make sure that all TRW Aftermarket ABS Sensors are precisely manufactured to our exacting standards and follow the same structure as OE parts. Because if the magnet or chip is out of place by just one degree, it can lead to a loss of signal strength by up to 30%, which can prove dangerous for drivers. Track and road testing takes place during both the development and production stages and with premium-quality polymers used in our entire ABS Sensor range, you can trust that you’re fitting your customer’s vehicle with an ABS Sensor of the very highest standard.

As part of the TRW drum brake and actuation range, our ABS sensors offer outstanding safety and protection for a variety of vehicles. With more than 540 part numbers in the ABS sensor field we have everything covered, allowing vehicles to process precise data at all times.

Our premium materials include shrink-wrapped signal and power cables, premium-quality silicon and precise cable ducts that ensure a perfect level of impermeability throughout the life of the sensor.

ABS sensors carry out a very simple function: they measure the rotational speed of the wheel and send the results to the ABS control unit. Regulatory action will then be taken by the car in line with this information. For example, if the ABS sensor registers varying wheel speeds (which could lead to a loss of adhesion) the valves in the ABS hydraulic section will reduce the brake pressure until it is rotating freely once again. This process takes place multiple times a second, which means ABS sensors carry out a job that no human could manage.

ABS sensors also provide the data that they collect to other advanced systems throughout the car such as ESP, ASR, hill descent control and the integrated navigation systems where fitted. As the most heavily stressed part of the braking system, they are incredibly important to the performance of most cars, which means faulty parts need to be fixed as soon as issues are detected.

TRW ABS sensors have undergone a huge amount of change and development since introduction to the market, which means they are available in a variety of designs depending on specific car requirements.

The two basic types are active and passive ABS sensors.

Active sensors need an external energy source to operate and are designed for toothed/magnetic encoder wheels. There are also two types of active sensors, Hall sensors and Magneto Resistive sensors.

- The Hall sensor reacts to changes in magnetic fields with a voltage difference which is transmitted to the control unit as a clearly defined square wave signal. Hall sensors record the wheel speed via a segmented disc that rotates with the wheel or a ring with alternating magnetic fields (magnetic encoder). Hall sensors are highly precise but require a precise installation position.

- The magneto-resistive AMR sensors are currently regarded as the most advanced but also the most expensive ABS sensors. Their great advantage over the other designs is their ability to detect the rotational direction of the wheels. The signal is extremely precise and AMR sensors are practically tolerant to their installation position. The encoder disc comprises magnetic arc segments which cause a clear change in resistance when passing the sensor. For the control unit, this change acts as a parameter for the wheel’s rotational speed and direction.

Passive sensors require a toothed wheel and only start to operate when the wheel reaches a certain rotational speed. They are larger than active sensors and less precise, which means their presence in modern vehicles is becoming scarcer, but given the simplicity of the design they are easier to check and often more robust. TRW passive sensors are built with a coil around a magnetic core, this permanent magnet creates a magnetic field. As the toothed wheel turns, it changes the field, which then induces an electrical current depending on whether there is a tooth or not.

Brake boosters

Brake boosters are a vital part of our TRW drum brake and actuation product range, helping you deliver outstanding quality for your customers. We test our brake boosters to every extreme, which means you can deliver a more reliable and consistent performance on the road for the drivers you serve.

By using the latest technology, as well as innovative, environmentally friendly techniques, we’ve proved that we’re at the forefront of the industry, giving you brake boosters that meet and beat today’s standards for automotive safety.

Our brake boosters offer you the following benefits:

- Original equipment (OE) quality

- Wide range of single and tandem brake boosters

- Unique tie-rod design meaning lighter and thinner parts for more efficient performance

- Great coverage, with almost 340 part numbers in the range, so you can serve more customers

All motorists now demand durability and resilience from their vehicles, which is why we invest in developing Drum Brake and Actuation products like Brake Boosters that are designed to last for longer. Choosing TRW Brake Boosters is a sure way of improving reliability and safety for your customer.

Brake Boosters have a very simple function: they’re designed to make it easier for drivers to push the brake pedal of their car using a vacuum assist system. Most modern cars have disc brakes, especially on the front wheels, which means they need power brakes and, therefore, a brake booster, to multiply the braking force. Not only cars with disc brakes use brake boosters, they are also widely used in vehicle with drum brake systems, to ensure safety without compromise.

With a collection of single and tandem Brake Boosters, we can cover a wide range of vehicle types, allowing you to deliver unbeatable levels of safety to the maximum number of drivers.

The unique tie-rod design of a TRW Girvac Brake Booster allows for the design to be thinner and lighter, resulting in a more efficient absorption of pressure from the booster. Our competitors don’t use this design, which means the shell of their boosters has to transmit the force through the booster. That’s yet another reason why TRW is the number one choice when it comes to brake parts.

One of the main issues that manufacturers often encounter with Brake Boosters is getting them to perform in extreme conditions, but TRW has countered this through our continued commitment to innovation. With a high-flow master cylinder, we’ve improved stability control at low temperatures, which means exceptional performance is maintained.

As an OE manufacturer of Brake Boosters we can supply you with exactly the same product quality that we deliver to vehicle manufacturers. And with 340 parts in the full range of Brake Boosters, you can offer that part quality to almost any customer.

Whether you’re dealing with a single or tandem Brake Booster, the instructions we provide are easy to follow, which means fitting is straightforward and simple. You can also be safe in the knowledge that TRW Brake Boosters are as environmentally friendly as possible, because we always use as little heavy metal as possible and recyclable materials whenever we can.

Brake cleaner

Fast acting, effective and developed with environmental concerns very much in mind, TRW Brake Cleaner is the market leading essential choice.

- Removes dirt rapidly and thoroughly

- CFC free

- Trichloroethane free

- Fast evaporating

- Safe on rubber components

- Delivered via powerful 500ml aerosol dispenser

- Efficient and easy to use at any angle, even upside down

- Kind to your hands

At TRW we have built a reputation for creating effective products that minimise environmental impact: it’s all part of our pioneering approach. The carefully formulated TRW Aftermarket Brake Cleaner is an important accessory that’s seriously effective and fast acting, but it’s also CFC free and contains no Trichloroethane.

Because we understand precisely what challenges you face when working on your customers’ vehicles, we create products that meet those challenges head on. Even in something as simple as a brake cleaner, attention to detail makes the difference.

The powerful 500 ml aerosol design makes it easy for you to get at difficult and restricted places in the brake system, and you will find that the spray works perfectly at any angle and even upside down. The task will be quicker and hassle-free, while the results will simply be better. We’ve thought carefully about TRW Aftermarket Brake Cleaner, so all you have to do is use it and appreciate the benefits.

With TRW Brake Cleaner you know you’re getting the same quality, effectiveness and value that you would with any of our components.

Brake fluid

Through our range of brake fluids, including the advanced DOT 4 and DOT 5.1 fluids, we can provide specialist brake care for a wide selection of vehicles, so that you can give better service to more drivers. And when you know that our products reduce corrosion and improve rubber performance better than any other brake fluid on the market, you know that, to give the best customer service, you should choose TRW.

The key benefits of choosing brake fluid from TRW Aftermarket are:

- Our brake fluids prevent water contamination and debris corrosion in master cylinder rubber parts

- DOT 3, DOT4 and DOT 5.1 brake fluid – brake fluid solutions for any type of vehicle

- Class leading testing techniques to keep you on the road

As vehicles become more advanced, our products need to keep up with the constant changes. Among the many latest developments in the industry is the inclusion of advanced braking systems in most new cars, including the electronic stability programmes (ESP). As ESP technology develops, brake fluid needs to act quicker to maximise the performance of the system and prevent cars from skidding.

Whenever drivers use their brakes, the brake fluid heats up and as brake hoses get older the amount of moisture that gets into the system increases, which means the brake fluid boiling point is lowered. This can be dangerous because if the brake fluid reaches boiling point through the use of the brakes, ‘vapour lock’ will occur, which can result in brake failure. This is why it’s important to change the brake fluid of a vehicle on a regular basis.

Owing to the exceptional quality of the TRW brake fluids, high-level performance is delivered for longer, but drivers should still change the brake fluid in their vehicle regularly to maintain performance and uphold safety levels.

As well as brake failure, not changing the brake fluid in a vehicle can lead to the master cylinder rubber parts becoming corroded. This can be detected easily and quickly by checking the colour of the brake fluid. If the fluid is dirty or has turned a dark colour, then it needs to be changed immediately, otherwise the braking systems could become damaged.

DOT 3 fluid needs to be changed every year, with DOT 4 and DOT 5.1 every second year. By doing this, you will prevent water contamination and debris from shortening the life of the whole braking system.

We aim to exceed expectations in all that we do, which is why we carry out more thorough tests and examinations of our brake fluids than anybody else. Safety critical testing areas include wet and dry boiling points and viscosity, which helps us to far surpass the requirements of the international DOT SAE 1703 specifications.

With the full range of brake fluids on offer from TRW, you can provide a suitable solution to all types of vehicles, regardless of age or specification.

DOT 3 brake fluid is designed for vehicles with drum brakes front and rear as well as hydraulic clutch systems. Further, some Japanese car manufacturers recommend DOT3 brake fluid for their vehicles with ABS and ESP.

We recommend the DOT 4 brake fluid for vehicles with disc brakes on the front and drum brakes on the rear. DOT 4 is also ideally suited to vehicles with disc brakes all round as well as those fitted with ABS. The special DOT 4 ESP has been added to the range to offer support for vehicles that are fitted with electronic stability programmes and ABS. If you’re choosing a brake fluid for a high performance cars, use the DOT 4 GP fluid, which has been designed specifically for racing applications. As is clear from the wide coverage that DOT 4 brake fluid provides, it is an excellent choice for anyone who needs to cater for a wide selection of vehicles.

The newest addition to the TRW brake fluid range is the DOT 5.1 ESP. Ideal for heavy, high performance cars, DOT 5.1 provides an extra level of safety, which can cope with ambient temperatures from -50oC up to +50oC, meaning brakes will perform to their best in all conditions.

DOT 5.1 ESP has been designed to complement the very latest ESP, with the low viscosity of the brake fluid allowing for a faster increase and decrease of the pressure needed for varying braking demands.

Brake hoses

Choosing TRW Brake Hoses gives you:

- A choice of 1,400 Brake Hoses covering 87% of the European vehicle parc

- The lowest volumetric expansion rate in AMECA tests, giving better stopping times and superior pedal feel.

- Exact concentric fitting holes to make sure there is a free flow of brake fluid

It’s easy to forget the importance of a Brake Hose among the many parts that make up a braking system.

In simple terms, the Brake Hose is a safety critical item on all vehicles. Operating under extreme stress whenever the brakes are used, they need to be checked regularly, as any faults will lead to a loss of brake fluid. This will mean a drop in pressure, which can lead to catastrophic brake failure.

The only way to find out whether a Brake Hose is working properly or not is to carry out a visual inspection. If cracks or leaks are visible it could be an indication that the whole brake network is damaged, as most brake parts wear out at the same rate as each other. TRW recommends that Brake Hoses are changed every five years or 31,000 miles (50,000 km) to make sure that safety isn’t compromised at any point.

Manufactured to TRW’s OE specification, our Brake Hose programme was awarded first place in an industry benchmark test for Volumetric Expansion carried out by the Automotive Manufacturers Equipment Compliance Agency (AMECA). The test revealed the exceptionally low volumetric expansion rate of our products compared to competitors, offering drivers superior pedal feel and improved stopping times.

TRW Brake Hoses have been crafted with modern cars in mind, as exact concentric fitting holes make sure there is a free flow of brake fluid. This is especially important for vehicles with advanced Anti-Lock Braking Systems (ABS) and Electronic Stability Control (ESC) as it allows for optimal pressure dump.

TRW provides high-pressure Brake Hoses made from rubber, Polytetrafluoroethylene (PTFE), steel or a combination of rubber and steel. Using these materials allows us to provide a product that has high resistance to humidity, chemicals and fuels and ensure that all of our hoses are produced in line with the Equipment Compliance Notification by AMECA. This means that all Brake Hoses from TRW are produced to not just meet but exceed the stringent OE standards, as well as the international specifications SAE J1401 and FMVSS 106.

Fitted with 100% zinc coated end fittings, our Brake Hoses are protected against rust, and with four layer high-quality fabrics, the hoses that we supply have exceptional flexibility and resistance to atmosphere as well as chemicals in fuels and grease.

Occupying the best European vehicle parc coverage position, as well as 1,400+ references and extensive coverage of Japanese and Korean vehicles, we can help you serve almost any customer. The range of Brake Hoses from TRW covers a wide range of manufacturers, including Honda, Toyota, Kia, Mazda, Nissan and Hyundai.

The only way to ensure that our hoses perform on the road in high-pressure situations is to test them to the extreme. This is exactly what we do, over and over again. Our testing process features:

- A pressure test up to 200 bar

- 100% leakage examination

- Destructive burst test up to 1100 bar

- Brake fluid compatibility test – conducted in an oven heated to 120oC for three days

- High pressure assessment test

- Volumetric expansion test

- Whip check to ensure a constant pressure of 20 bar and at 800 revs/minute

- Tensile test

Clutch cylinder

Being one of Europe’s top braking hydraulics manufacturers, TRW Aftermarket offers quality and versatile choice. We supply clutch master cylinders and clutch slave cylinders in light but strong aluminium and tried, tested steel, cast iron and plastic.

A TRW Aftermarket Clutch Cylinder gives you:

- A robust component manufactured in steel, cast iron, lightweight aluminium or plastic

- A clutch cylinder that is always 100% end of line tested

- Steel and cast iron parts coated with the latest chrome 6-free ‘silver’ finish for durability and minimal environmental impact

- Clutch cylinders made to the highest OE standards

- Master cylinders made for lightness, toughness and dependability

Steel and cast iron TRW Aftermarket Clutch Master Cylinders and Clutch Slave Cylinders are coated with the latest chrome 6-free ‘silver’ finish. This means compliance with EU directive EU 2000/53/EG, less damage to the environment and a longer clutch cylinder lifespan, so you can offer parts that won’t give you comebacks – except for repeat customers coming back for more.

In the automotive industry, the TRW name on a clutch master cylinder or clutch slave cylinder has always been a guarantee of premium product quality, and recent innovations show that we’re still working to enhance their quality even further. Our aftermarket clutch cylinder range now incorporates the latest advances developed for original equipment. Put this together with our extended range of aluminium wheel cylinders, which deliver reduced vehicle weight as well as extended part lifetime, and the same chrome 6-free finish as our brake master and wheel cylinders – plus our extended guarantee for 3 years or 60,000 miles (100,000 kms) – and our clutch cylinder range offers outstanding value and premium quality.

TRW Aftermarket Clutch Master Cylinder and Clutch Slave Cylinder components give you 100% quality because we test them 100%. Drivers need to know that the invisible safety in their cars works every time and that means giving them every challenge in the lab and on the road. That’s why all TRW Clutch Cylinders are 100% end of line tested to ensure that they conform to TRW’s stringent original equipment standards. We evaluate every element of the cylinder to maximise safety, and with rigorous testing in the lab with up to one million cycles, you can expect an extremely robust part when you choose TRW Aftermarket components. In fact, we’re so confident of the quality of our clutch cylinders that we offer an additional three-year guarantee in the event of a defect in material or workmanship.

Master cylinders

With a TRW Aftermarket Brake Master Cylinder you get:

- A robust brake cylinder manufactured in steel, aluminium or cast iron

- The option to choose light aluminium bodies to reduce vehicle weight

- A high coverage range of premium quality parts, all supplied with fitting accessories

- A protective, durable and environmentally friendly coating with the latest chrome 6-free ‘silver’ finish for steel and cast iron models

- Original equipment spec rubber seals and dust caps to resist ageing

TRW Aftermarket offers 1334 part numbers in the brake master cylinder range, which covers 72% of the European vehicle parc. What’s more, our extensive range includes brake master cylinders for most Asian car applications. With TRW Aftermarket Brake Master Cylinders you can give your customers excellent service from a premium range that offers increasingly wide coverage, all backed by more than 100 years of TRW experience as an original equipment aftermarket leader.

To meet the growing need across the automotive world for lighter components that maximise safety, we’re increasingly supplying our brake master cylinders in lightweight aluminium bodies as well as in steel or cast iron. Our aluminium brake master cylinders reduce weight, while retaining performance and guaranteeing long part lifespan. As a global leader in the design, development and manufacture of safety critical, original equipment braking, steering and suspension parts and systems, we’ve invested in innovation to deliver lightweight parts that deliver a heavyweight performance, and will continue to do so in the years ahead.

The exceptional performance of TRW Aftermarket Brake Master Cylinders is available from a high coverage range of parts, all supplied with fitting accessories, so you can fit unmatched original equipment quality fast. Everything we do at TRW has one objective – to make sure that garages and installers are able to satisfy customers profitably – and that’s been proven time and again right across our brake master cylinder range.

The steel and cast iron brake master cylinders in our range are coated with the latest chrome 6-free ‘silver’ finish. That means longer brake master cylinder lifespan and less damage to the environment – and you’ll be in line with EU directive EU 2000/53/EG. As the need for safety and the speed of technological change creates a need for ever more complex parts, we’ll give you the innovations that mean you can serve better products to more customers to keep your business turning.

We evaluate every element of each brake master cylinder to maximise safety. We do this through meticulous testing. All TRW Aftermarket Brake Master Cylinders are 100% end of line tested to ensure that they conform to TRW’s stringent original equipment quality standards, and we also put them through rigorous testing in the lab with up to one million cycles. In fact, we’re so confident of the quality of our brake master cylinders that we offer an additional three-year guarantee in the event of a defect in material or workmanship.

All TRW Aftermarket Brake Master Cylinders are fitted with original equipment specification rubber seals and dust caps, which means they are far more resistant to ageing. In the automotive industry, the TRW brand on brake master cylinder castings and dust caps has always been a guarantee of premium product quality, and our recent innovations show that we’re still working to enhance their quality even further. Our aftermarket range of brake master cylinders now incorporates the latest advances developed for original equipment, including fixed seals. Put this together with our extended range of aluminium wheel cylinders, which deliver reduced vehicle weight as well as extended part lifetime – plus our extended guarantee for 3 years or 60,000 mile (100,000 km) – and our brake master cylinder range has the seal of quality in more ways than one.

So how important is the quality of a brake master cylinder? The simple answer is vitally important. The ‘invisible’, safety critical parts of the braking system, hidden under a drum or inside the car, are often not given the same degree of consideration as brake discs and pads. But if drum brake and actuation system components such as brake master cylinders, brake hoses or brake fluid are not working properly it can contribute to a serious reduction in braking performance. Checking these parts regularly and fitting good quality, OE matching aftermarket products when necessary is essential. That’s why the premium quality and wide coverage of our TRW Aftermarket range of brake master cylinders enables garages, installers and end users alike to maximise safety for almost any vehicle.

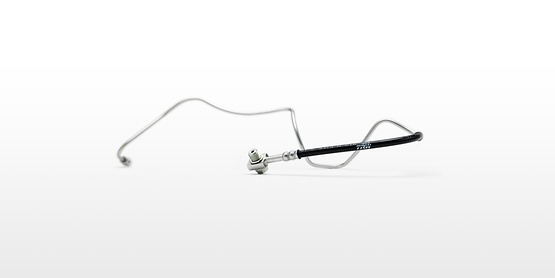

Handbrake & clutch cables

And choosing TRW offers you reassurance that all of our products will meet and exceed the international regulations, delivering a truly class-leading performance.

The main advantages of a TRW Aftermarket Handbrake and Clutch cable are:

- Original Equipment (OE) producer

- High quality materials – multiple strand rope coated in MoS2 improving cable strength and elasticity

- Automatic adjusters for maintenance-free parts

- Variety of cable designs to cover different vehicle types

Handbrake cables

TRW Aftermarket Handbrake and Clutch cables are tailor-made for each individual car, which means you can offer every driver a personalised level of service that matches their specific driving needs.

Our Handbrake cable product range is growing all the time and we have set ourselves the target of becoming the number one in parc coverage. With 923 references across 74% of the European vehicle parc, we are one of the market leaders when it comes to handbrake cables.

Our selection of handbrake cables includes products made from multiple strand rope, which enhances flexibility because the wires are able to slide over each other. We also coat the cables with molybdenum disulphide (MoS2), which reduces friction and improves sliding even more. The result is a longer lasting product that is protected from hard corrosive actions by the high-quality surface treatment provided by TRW.

TRW Aftermarket Handbrake Cables are created using multiple smaller wires that combine to make thicker ropes. This is a pioneering technique that leads to better cable strength, flexibility and the perfect degree of sliding within the sheath. All handbrake cables are also maintenance free, which means drivers never have to think about them again once they’ve been installed.

When cables become damaged they need to be changed, otherwise they stop working and this can lead to the parking brake not being released properly, which can result in much more serious issues if not fixed. Brakes can become overheated and a grinding noise can indicate wear and tear, with the worst-case scenario that the car won’t move. This occurs when the polyamide cover gets damaged, meaning water and dirt gets into the system and corrosion occurs, leading to the outer diameter expanding and the handbrake of clutch cable not sliding as freely as it should do.

The first place to start when you are testing the handbrake is to make sure there is no significant dragging during a rolling road test. If there is, then it could be because there is an issue with the cable. To test the parts properly, with a drum brake system for example, you need to carry out the following steps:

- Remove the drums

- Actuate the handbrake lever and make sure the mechanism is working properly

- Release the handbrake lever – the shoes should go back to their rest position

- If you are still unsure, you can disconnect the cables and check them individually

You should make sure that you always carry out these tests before you add new parts to any car.

Clutch cables

TRW Aftermarket has everything covered when it comes to clutch cables, with more than 300 references. We are aiming to be the number one in parc coverage through assertive growth plans that will see our already extensive range grow even further. Our market-leading availability is something that we are really proud of and it means we can meet your needs for almost any vehicle.

Most of our clutch cables can easily be fitted by one person, which makes the process of changing them much quicker and more efficient. The general wear of the clutch means that the clutch cable needs occasional adjustment, but with the automatic adjusters, there’s no need to worry about this. The self-adjusting mechanism will operate when needed, ensuring that our clutch cables are maintenance-free.

High-quality spiral rope is covered by nylon as well as MoS2 that operates as a self-lubricant, while the trapezoidal sheath has an inner plastic pipe that enhances flexibility and improves smoothness, for added protection from rubbing against the metal. All of this advanced technology means a TRW Aftermarket Clutch Cable performs better than competitors for longer.

Showing our dedication in providing a wide range of product types within the clutch cable sector, we have a variety of techniques to cater for a variety of vehicles. These include:

- Braided wires that together build a rope

- Braided ropes that together build a cable – resulting in higher flexibility

- Braided wires to build a cable – resulting in increased strength

- OE always dictates which design is used depending on the requirements and with grease between all of the ropes and wires, low friction is assured.

![ZF [pro]Academy ZF [pro]Academy](/media/master/service-images/zfa_pc_training_img_clutch-centering-tool-01_wxh_cmyk_2017-11_un-progressive_bs_32_xl_4.jpeg?v=1125971310)