The proper disposal of shocks is an important topic for ZF. After all, environmental protection is a key corporate objective. According to our corporate philosophy, product quality includes not only optimum operating properties, long service life and convenient installation, but also saving resources, recycling and preserving the environment. For us, this means developing, producing and disposing of products in environmentally compatible ways.

All SACHS damper packages contain clear, multi-language information on the disposal of shock absorbers. At a glance, the mechanic can see all the important information he needs on how and where to dispose of defective shock absorbers.

The easiest way is to take them to a certified disposal company. However, if you want to dispose of them yourself in the workshop, perform the following steps, always observing accident prevention and environmental protection regulations:

How-to-guide

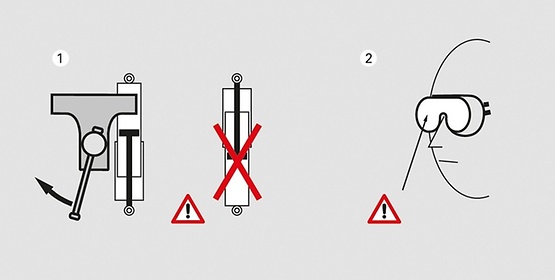

1. Clamp damper in a vise, with the piston rod always pointing down.

2. Wear protective goggles.

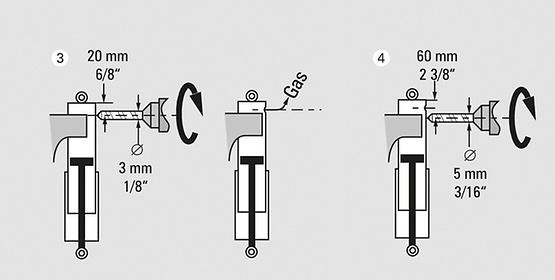

3. For gas-filled dampers, first drill a hole into the gas reservoir (ø 3 mm) and allow the gas to escape.

4. Drill a hole into the oil chamber (ø 5 mm).

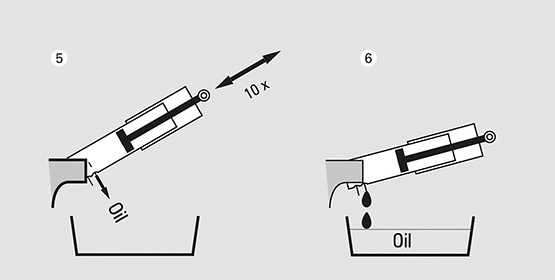

5. Pump the oil out and catch it in a suitable vessel.

6. Allow oil to drip out completely.

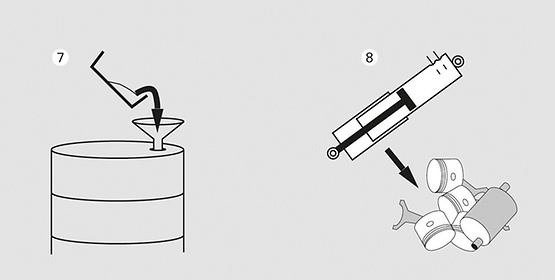

7. Dispose of the oil in a specified used-oil collection tank.

8. Dispose of empty damper as scrap metal.

If you observe these eight points and proceed correctly, it is easy to dispose of dampers in an environmentally friendly way.

ZF Aftermarket product range

Discover the complete portfolio of suspension systems in our product catalog.