SACHS Continuous Damping Control (CDC) is one of the most popular ZF products.

How-to-guide

More and more automotive manufacturers are opting for the continuously variable damping system Continuous Damping Control (CDC) in their vehicles. It permanently monitors influencing factors such as the road condition, load, vehicle body acceleration and driver’s actions. The vehicle sensors register all changes. From this, the control unit determines the optimal damping requirements and thus reduces the need for maintenance.

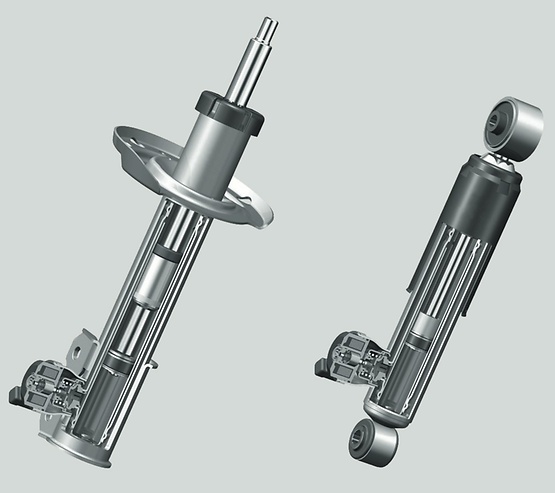

The proportional valve adapts the damping force for every single wheel in milliseconds. This means better ride comfort and dynamics, less rolling and pitching motion and a shorter braking distance due to better road contact. These are advantages that are increasingly also used in buses, coaches, trucks and agricultural machinery.

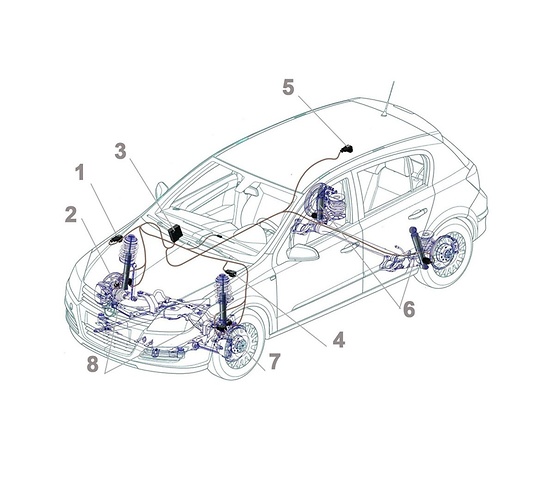

1 Body sensor, front right

2 Sensor, suspension strut right (wheel acceleration)

3 CDC control unit

4 Body sensor, front left (body acceleration)

5 Body sensor, rear (body acceleration)

6 CDC damper, rear

7 Sensor, suspension strut left (wheel acceleration)

8 CDC suspension struts, front

If there is an electrical or mechanical fault, CDC dampers must be checked just like conventional dampers and replaced if necessary. After installation, the CDC damper must be calibrated in the vehicle using a diagnostic tester.

The CDC system is capable of performing a self-diagnosis, but it only recognizes electrical faults, not mechanical malfunctions. In the case of a fault, the CDC indicator lamp on the dashboard lights up. To narrow down the problem, a diagnostic tester (for example the Bosch KTS) is required. It can be used to read out and delete the error memory. Depending on the vehicle, it is also possible to compare the nominal/actual values in order to check the sensors of the CDC system.

When you are installing CDC dampers, always replace them in pairs. To guarantee full functionality, the add-on components – compression stops, protection tubes and suspension-strut mounts – must also be checked for wear before installing the dampers. Every time you install dampers, always replace the service kit (protection tube and compression stop).

Here is another important tip to ensure you replace CDC systems successfully: Avoid tension or stress on the dampers by tightening the fastening screws only when the vehicle is standing on its wheels. After that, measure and readjust the wheel geometry if necessary.

After replacing the CDC damper, check the system functions. When the ignition is switched on, the CDC indicator lamp in the car must go out after approximately ten seconds. That's all: Your CDC system is ready for use again.

ZF Aftermarket product range

Discover the complete portfolio of suspension systems in our product catalog.