Together with shocks and suspension strut mounts, suspension springs fulfill important safety and comfort functions. This is why you should regularly inspect the components and replace them in the event of corrosion damage or fractures.

How-to-guide

Defective springs negatively affect vehicle handling and road safety: They extend the stopping distance because they can no longer correctly absorb the forces which occur upon deceleration. In addition to that, tires lose road contact more easily and wear more quickly. In fast or tight corners, the car has a greater tendency to move sideways and will break away earlier. If the vehicle accelerates or brakes, the body is subject to substantial movement. Furthermore, the ground clearance is reduced, which in turn increases the tendency to "bottom out". Not least, damaged springs reduce the service life of dampers.

SACHS offers free service information to download on this and other topics.

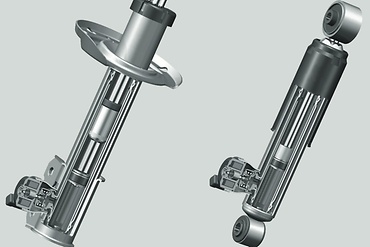

As only fully functional suspension springs can work perfectly with the other chassis components, experts at ZF Aftermarket recommend regular inspection at an automotive specialist workshop: If springs show severe corrosion and fractures, then workshop customers should have them replaced. The instructions on changing suspension springs are clear: The guiding principle is that the springs should always be replaced in pairs per axle. This significantly increases driving safety and also comfort and effectively protects the dampers, suspension-strut mounts and tires from premature wear.

There is a clear rule when changing suspension springs: Always replace them in pairs per axle. This significantly increases driving safety and also comfort and effectively protects the dampers, suspension-strut mounts and tires from premature wear. Therefore, replacing in pairs also helps prevent unnecessary costs.

ZF Aftermarket product range

Discover the complete portfolio of suspension systems in our product catalog.