Your vehicle is engineered for longevity, traveling thousands of miles without major repairs. Yet, crucial elements like shock absorbers wear out over time, impacting automotive suspension. This guide dives deep into the intricacies of how shock absorbers work and their role in maintaining ride quality and safety. Additionally, the blog also offers essential insights into identifying signs indicating the need for shock absorber replacement, ensuring your vehicle performs optimally and safety standards are maintained.

Understanding Shock Absorbers: How They Work

Shock absorbers, also referred to as dampers, are indispensable components of your vehicle's suspension system, ensuring a smooth and stable ride. They function by regulating the movement of the springs and suspension, thereby guaranteeing constant tire contact with the road.

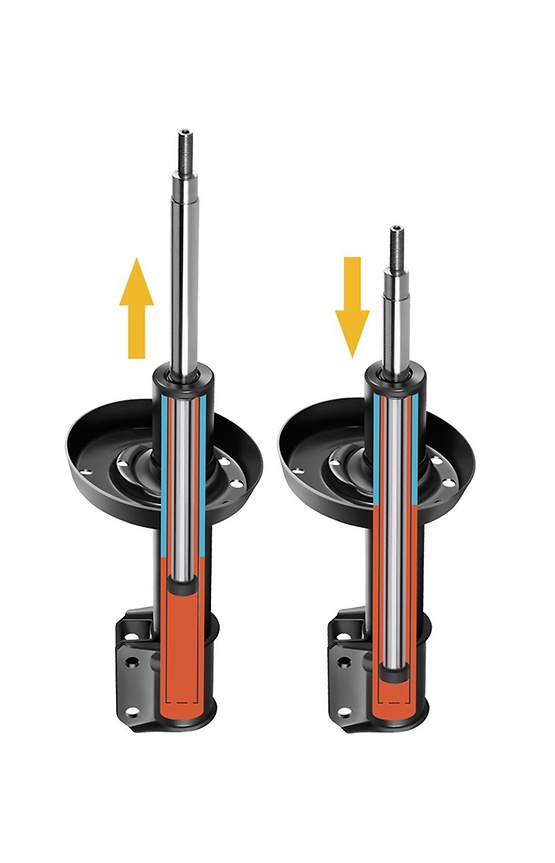

When the vehicle encounters uneven surfaces, shock absorbers absorb the kinetic energy generated by the suspension's motion. This process involves a piston moving up and down within a pressure tube filled with hydraulic fluid. As the piston moves, the fluid is pushed through tiny orifices, creating resistance that dampens the spring motion. Consequently, this action smoothes out bumps and vibrations, enhancing overall driving comfort and stability.

How-to-guide

As discussed earlier, shock absorbers are integral to a vehicle's suspension system, damping the oscillations of the suspension springs to maintain tire contact with the road and enhance ride comfort. They are hydraulic devices that absorb and dissipate the kinetic energy generated by bumps and uneven road surfaces. This is achieved through a piston moving within a cylinder filled with hydraulic fluid, creating resistance that counteracts the suspension's movement. By controlling compression and rebound, shock absorbers ensure a smoother, more stable ride, improving vehicle handling and safety.

Note: Regular maintenance and replacement of worn-out shock absorbers are essential to uphold optimal performance on the road.

In the automotive suspension system, springs absorb road bumps and dampers (shock absorbers) slow the movement of the springs, thus preventing them from oscillating uncontrollably. Together, they maintain vehicle stability and passenger comfort by minimizing road noise, bumps and vibrations.

Worn out shock absorbers can significantly affect the comfort, safety and handling of your vehicle, making it crucial to recognize the signs that they may need to be replaced. Over and above the few mentioned below, if your vehicle’s "nose dives" during braking or the rear squats excessively under acceleration, it's likely that the shocks are no longer functioning properly. Here is a detailed lowdown to help you understand the key signs to act in time.

Worn out shock absorbers can significantly affect the comfort, safety and handling of your vehicle, making it crucial to recognize the signs that they may need to be replaced. Over and above the few mentioned below, if your vehicle’s "nose dives" during braking or the rear squats excessively under acceleration, it's likely that the shocks are no longer functioning properly. Here is a detailed lowdown to help you understand the key signs to act in time.

One of the first signs of worn shock absorbers is uneven tire wear. If your tires show patches of uneven wear, or if one side of the vehicle's tires is more worn than the other, this can indicate failing shocks.

If your car continues to bounce after hitting a bump or during wind gusts, it’s a clear sign that your shock absorbers may be degraded. This excessive bouncing can affect vehicle handling and increase stopping distances.

A noticeable decrease in steering response, stability at high speeds, and corner handling are all symptoms of worn shock absorbers. You might find your vehicle "rolling" more when turning or changing lanes.

Visible leaks from the shock absorbers are a definitive sign that they need to be checked. If you see oily residue on or around the shock absorber, it means that the seals may be broken and the absorber is losing fluid.

Deciding when to change shock absorbers is key to maintaining the performance and safety of your vehicle. Generally noticeable changes in the driving experience, such as increased braking distance, excessive vehicle sway or roll during turns, and a general instability at highway speeds can suggest that the shock absorbers are no longer performing effectively. If the ride of the vehicle feels unusually bumpy or jarring, or if you hear strange noises like knocking or rattling coming from the vehicle's suspension, these are also signs that the shock absorbers may need to be replaced. Regular maintenance checks can help identify these issues early, ensuring that shock absorbers are replaced before they lead to more serious problems or safety concerns. Here are some prominent ones that will help you to quickly know, it's the time:

Manufacturer Recommendations

Always start with the manufacturer’s guidelines, which typically suggest inspection intervals and replacement periods based on mileage. These recommendations are crucial as they are tailored to your vehicle's specific build and expected lifecycle, such as car suspension components. Manufacturers might also provide specific symptoms of wear or failure to watch out for, which can be particularly useful for early detection and prevention of further suspension system issues.

Mileage and Driving Conditions

Shock absorbers generally last anywhere from 50,000 to 100,000 miles. However, this varies based on driving conditions, road quality and how the vehicle is used. Frequent off-road driving or travel on poorly maintained roads may accelerate shock absorber wear. Moreover, driving habits such as aggressive braking and high-speed driving can also contribute to faster degradation, necessitating more frequent car shock replacements.

Visual Inspection

It is crucial to understand how shock absorbers work. Then only you will be able to find out the flaws. Regular checks for physical damage to the shock absorbers, such as dents or heavy corrosion, and signs of fluid leakage are essential. Visible damage or oil streaks on the shock absorber body are signs that they may not be functioning correctly. If you're unsure, a professional mechanic can perform a detailed inspection using specific tools to measure the effectiveness of your shock absorbers. Additionally, listen for unusual noises like clunking or rattling during drives, which can further indicate issues with the shock absorbers.

Understanding when and how to replace shock absorbers can save you from more costly repairs down the line and keep your vehicle safe and comfortable on the road. If you suspect your shock absorbers are failing, consult with a trusted mechanic to verify your findings and plan for a replacement if necessary. Proper maintenance of your car suspension system not only prolongs the life of your vehicle but also ensures your safety on the road.

FAQs

Shock absorbers should typically be replaced every 50,000 to 100,000 miles, but this can vary based on driving conditions, vehicle type, and manufacturer recommendations. Regular inspections can help determine if they need to be replaced sooner.

Yes, worn shock absorbers can affect other vehicle components. Poor shock absorption can lead to increased wear on tires, suspension components, and steering systems due to uneven road force distribution and increased vibration.

Signs that you may need to replace your shock absorbers include unusual tire wear, excessive bouncing after bumps, leaking fluid from the shock absorbers, decreased handling ability and an overall rough ride.

To prolong the lifespan of your shock absorbers, avoid overloading your vehicle, drive cautiously over potholes or rough roads, and perform regular maintenance checks to identify and address issues early. Keeping your vehicle’s suspension system well-maintained, including proper wheel alignment and balanced tires, also helps reduce unnecessary stress on shock absorbers.

ZF Aftermarket product range

Discover the complete portfolio of suspension systems in our product catalog.