Engines, gearboxes and axles cause a multitude of vibrations during operation of a motor vehicle. Numerous rubber parts are installed to absorb these vibrations and keep them away from the car body and the passenger compartment.

About 5 % of the 10,000 or so parts of a car consist of rubber in various compositions. This is therefore a rather sophisticated, complex material.

Rubber bushes are installed in the suspension. They improve handling during steering and braking, which is particularly important on uneven road surfaces.

The functions of these parts are:

- Allowing a set steering movement

- Insulating noise

- Transmitting forces

- Absorbing vibrations

It requires a closer look to see which forces and influences act on a car suspension. The video for this how to guide provides an impression of this. It shows a front axle test bench during a test.

How-to-guide

Engine and gearbox are connected to the body through rubber elements to prevent the transmission of vibrations and noise to the body.

Even without mechanical stress, all rubber elements are subject to a natural aging process.

Extreme temperature fluctuations, exposure to sunlight, ozone, snow, ice and road salt are all factors that additionally accelerate the aging process of these components.

This means, for example, that the shock-absorbing properties of a rubber bearing decrease over time. This leads to suspension noise on bad roads and affects vehicle handling.

The sophisticated tasks of the rubber parts require regular checks to prevent expensive consequential damage to other vehicle components caused by the defective parts.

Several rules have to be observed for replacing and changing TRW bushes.

The rubber bush on a control arm may only be tightened while the wheels of the vehicle are on the ground to avoid twisting and therefore applying pre-tension to the bearing. This would lead to a decreased service life.

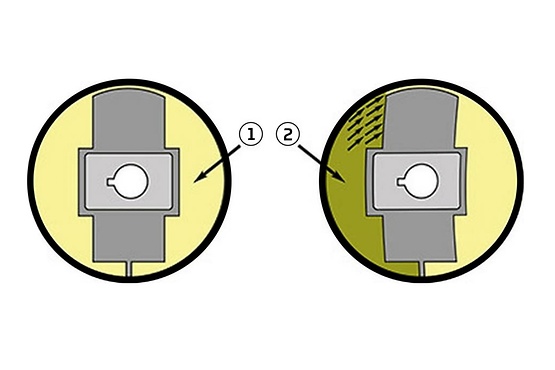

Some rubber bushes have different shock absorbing properties in the different directions of the load due to their design.

For these parts, it is particularly important that they are installed in the correct position (see XZS167). The correct installation position is indicated with markings on the bushes.

If this is not observed, poor handling and noise may occur after installation.

Due to the differing designs, the bushes can, for example, have a greater damping behavior during braking than during acceleration.

Whether a bearing is a full rubber bush or a hydro bearing is relatively easy to see on the component itself. On a hydro bearing, the hydraulic bearing is pressed into the bearing shell rather than vulcanized. This produces a visible edge between the rubber and the metal. Full rubber bearings are not pressed in but vulcanized which does not produce such an edge.

Hydraulic bearings contain a hydraulic fluid which can move freely.

If the bearing is deformed through suspension movements, this fluid flows into the inside of the bearing through narrow channels. This generates a flow resistance which in turn creates the desired damping.

During a slow, even motion, the damping rate will also be low because the hydraulic fluid has enough time to flow from one side to the other.

Fast, sudden movements on the other hand create a high level of damping because the hydraulic fluid is held back in front of the damping channel and cannot change sides quickly enough.

Nice-to-know

Conclusion

The faster the motion, the greater the damping. Due to their design, hydro bearings offer maximum safety and comfort.

Note: ZF Aftermarket recommends always replacing suspension parts in pairs because both parts have the same mileage and were exposed to the same stresses.

After replacing suspension parts, always carry out an alignment and adjust the suspension if necessary!

It is always worthwhile checking the rubber parts at regular intervals to save your customer costs and trouble.

ZF Aftermarket product range

Discover the complete portfolio of suspension systems in our product catalog.