Despite the ever growing proportion of electrical steering systems (from electrohydraulic right through to fully electronic steering), there are still new vehicles and plenty of older models that have conventional power steering. In these models, the power steering pump is driven directly by the vehicle's engine via a belt.

How-to-guide

TRW offers remanufactured OEM-quality power steering pumps for these vehicles. The servo pumps are supplied in accordance with the scope of delivery of the vehicle manufacturer. This means that some models are supplied with a belt pulley or adapter flange and others without these attachments.

During assembly, there are various points to be observed for the different versions. If the pump is delivered without a belt pulley or adapter flange, these components must be retrofitted on to the new part using a suitable special tool.

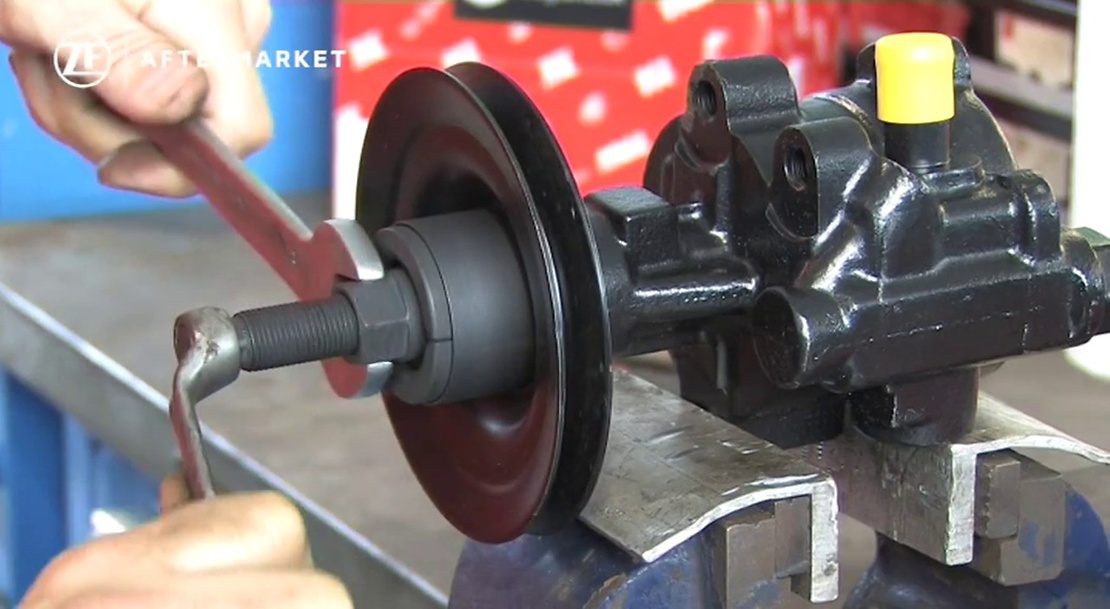

These instructions show how to retrofit a belt pulley using a commercially available special tool box.

Before removal, measure the clearance of the belt pulley or adapter flange to the pump housing (observe the axial clearance of the input shaft) so that they can be refitted later in the optimum position. This prevents the V-belt from running askew (not parallel), which accelerates wear or even causes the V-belt to come away from the pump wheel.

For removal, the special tool, as seen in the video, is positioned on the part to be retrofitted - in our case, the belt pulley. Then the belt pulley can be carefully pulled out of the pump input shaft. The removed belt pulley is then positioned on the remanufactured pump and fitted on to the input shaft using the special tool, observing the previously measured clearance. No pressure is applied to the shaft when using the tool. Incorrectly press-fitting using too much pressure may damage the housing or the pump wheel. The parts must not be press-fitted, otherwise the shaft may be pushed into the pump and cause irreparable damage.

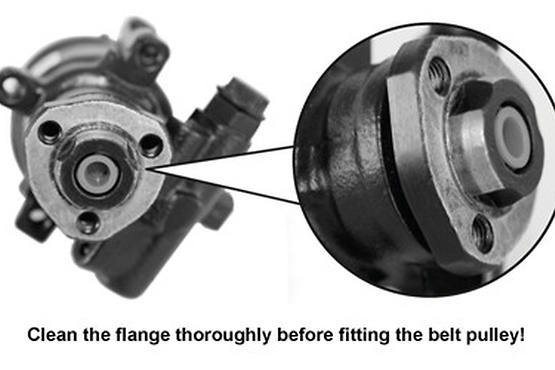

If the remanufactured part is delivered with a flange or if one was removed from the old part, before fitting the pump in the vehicle, check that the belt pulley is flush on the adapter flange and, if required, remove any excess anti-corrosion agent.

If the belt pulley is not lying completely flush on the flange, there is a risk of the attachment bolts becoming loosened and the belt pulley coming away from the input shaft as a result of the belt's high tensile forces. This would immediately cause power steering to fail! The belt pulley may also damage components in the motor compartment.

Note: Bolt locking must be used with the attachment bolts and they must be tightened to the torque specified by the vehicle manufacturer.

Nice-to-know

ZF Aftermarket product range

Discover the complete portfolio of steering components in our product catalog.