Overhaul & Repair

Overhaul & Repair (ZF & Non-ZF)

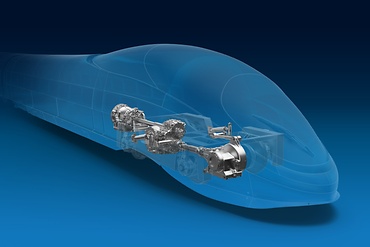

By accessing the latest & most detailed technical information, ZF Aftermarket provides an unrivaled repair and overhaul service for both its own and Multi-brand respective Non-ZF gearboxes. Every rail transmission requiring repair is overhauled to, then tested and approved in compliance with, volume production test specifications. This not only enables the highest levels of on-going vehicle performance, but also helps to extend vehicle life, maximizing uptime and improving overall efficiency.

Discover our benefits

- Comprehensive solutions

For full range of ZF Rail products and Multi-brand respective Non-ZF gearboxes - All components fully tested

Testing carried out to original factory standard - Latest development standards

Continuous exchange between ZF Corporate, ZF Process Management & ZF Aftermarket

Spare Parts & Units

Quality spare parts and units

All spare parts for rail applications are manufactured and tested in accordance with identical regulations and ZF Group standards. Employing innovative manufacturing techniques and accessing the latest & most detailed technical information, the aftersales offer from ZF Aftermarket comprises OE quality, durable, reliable spare parts. This not only provides optimum performance and extends vehicle life, it improves overall efficiency and maximizes uptime.

- Unrivaled distribution network

Working closely with other locations allows a joint planning phase - Highest OE quality

Using only genuine OE quality ZF spare parts - Volume production part fit

Precision parts designed for seamless integration

Repower

Repower

Repowering trains offers a vital solution to improve economy, performance, and sustainability in the rail industry. By upgrading outdated locomotives with modern, energy-efficient engines and power systems, we can significantly reduce CO2 emissions.

Systems (Wheelsets / Bogies)

Systems (Wheelsets / Bogies)

Unlock unparalleled performance and reliability with our top-of-the-line overhaul of wheelsets and bogies. Discover our overhaul services for multi-brand power wheelsets and bogies and benefit from our supply of bogie components. Keeping you on track is our passion.

Advanced conditional monitoring

Digitalization not only streamlines maintenance processes but also reduces downtime, optimizes resource usage, and minimizes environmental impact. By integrating advanced digital solutions, rail operators can significantly enhance the longevity and performance of their fleets, ensuring a more sustainable future.

ZF Aftermarket offers a broad set of solutions tailored to the needs of modern rail fleet maintenance.

Seamless gearbox monitoring with Smart Oil Plug®

Smart Oil Plug® – our wireless, sensor-based solution developed in conjunction with industrial data experts Transmission Dynamics – transforms global maintenance practices. The system provides real-time, wireless gearbox condition monitoring – improving efficiency and maximizing uptime. It can be seamlessly adapted to any rail gearbox application to accurately measure temperature, oil, debris and vibration data; generating an alarm if there's a deviation from normal operation. Its wireless nature allows for continuous under-train mounted operation, without fear of damage from flying ballast or vegetation.

Comprehensive condition monitoring with connect@rail

The combination of the wireless Heavy Duty TAG sensor and the VCU Pro Onboard Unit offers a cutting-edge solution for remote condition monitoring. The Heavy Duty TAG is a robust Bluetooth® sensor designed for industrial applications, recording acceleration and tilt to detect anomalies in wheel-rail contact. This helps in timely maintenance and reduces the risk of unexpected failures. The VCU Pro Onboard Unit, a telematics gateway, processes and transmits the sensor data such as temperature and acceleration, ensuring comprehensive monitoring via the ZF IoT Cloud. This integration enhances safety, efficiency, and reliability, providing rail operators with real-time insights for better decision-making.

Looking for your perfect solution?

You want to know which solution is the best for your particular fleet's needs? Just contact us – our experts will find the right solution.

ZF Service Expertise

ZF Service Expertise – Local and worldwide

Offering a local service on a global scale means that ZF Aftermarket is always available to its customers wherever they are in the world, whenever they need help. With a carefully controlled global footprint, ZF Aftermarket operates in the most sustainable way possible from more than 30 dedicated facilities. And by working with a service network of more than 650 partners help is always close at hand.

Benefit from ZF Aftermarket's global expertise all around the world!

- Dedicated global facilities

Over 650 ZF Service Partners - Fast reaction time

Dedicated, fully trained rail service specialists - ZF's service expertise

Designated overhaul facilities for ‘all types' of rail drives

Contact

Any questions? Let's chat!

If you would like to learn how ZF Aftermarket can enhance your rail fleet please contact us. We are looking forward to discussing the solutions that fit your particular needs.