How-to-guide

In this case, the pump is mounted in the front wheel arch. With the vehicle raised on a two post lift, remove the appropriate wheel followed by any wheel arch linings as shown. This will expose the pump and its mounting. Before proceeding any further, compare the new received part with the one currently fitted to the vehicle. Make sure all connections, both electrical and mechanical, are fixing points are identical.

Firstly, disconnect the electrical connections to the pump and inspect the vehicle harness connector to ensure there are no signs of damage and corrosion due to water ingress. Also check that the connector of the new pump is identical with the one actually fitted in the car.

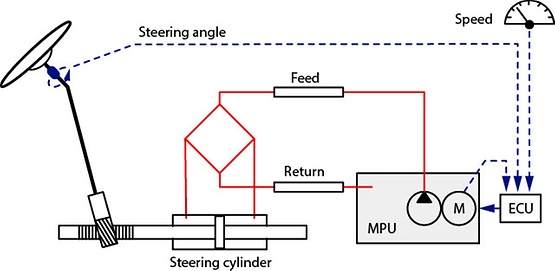

Now remove the fluid pipes – firstly the outlet pipe at the bottom of the pump unit followed by the top return pipe to the reservoir unit. Catch a quantity of escaping fluid on a white cloth or paper towel and check the fluid for dirt and / or metal shavings. If there is any sign or you are in any doubt, flush the complete steering system.

Next, remove the fixing bolts for the pump unit and carefully remove the pump and drain any fluid in the reservoir into a waste fluid disposal unit. Now you can offer the new pump into position, feeding the wiring harness into the appropriate place. Before securing the pump rigidly in position, re-attach the hydraulic fluid pipes starting with the high pressure outlet onto the motor pump unit ensuring the fixing screw is tightened with the correct torque.

Reattach the pipe unit to the reservoir and secure with the clip as shown. Once this is in place, you can now reattach the mounting brackets and bolts and secure the pump rigidly in position. Reattach any mounting clips to the wiring harness. Reconnect the harness as shown and attach to mounting bracket to ensure a secure installation.

Inside the engine bay, remove the fuse box cover and the headlamp bulb covers to allows access to the filler cap on the reservoir. Fill the reservoir with new hydraulic fluid. Fill the reservoir to the correct level. Once this is done, start the engine and bleed the steering system following the instructions recommended by the vehicle manufacturer.

Clean the pump and mountings with brake cleaner to ensure no hydraulic fluid remains on the surfaces (it is highly corrosive). Reattach the wheel arch linings and refit the road wheel following normal best practice.

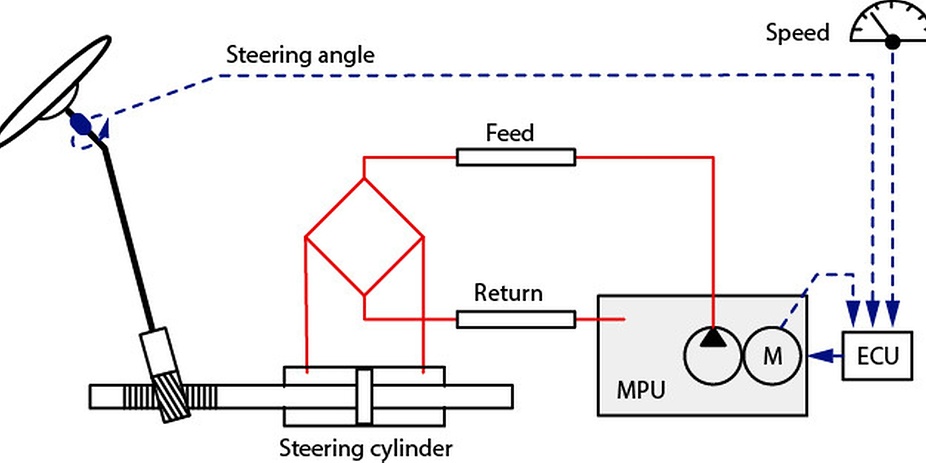

Depending on the pump configuration being fitted, it may be necessary to activate the steering pump within the vehicle CAN BUS and / or select the correct software map according to the vehicle specification. This must be carried out using a suitable diagnostic tool. Once this is done, read and clear any fault codes.

Nice-to-know

ZF Aftermarket product range

Discover the complete portfolio of steering components in our product catalog.