The problem of slipping clutches is very wide-ranging. For example, the clutch of a vehicle may slip only at high speeds. Other drivers complain that their clutch slips when the engine is cold, during starting, when setting off, or in first speed position. Another notices the clutch slipping through much of the period of acceleration, and yet another says his clutch slips after chip tuning. Clutch slipping symptoms and causes are just as varied as the symptoms. Even a brand new clutch can be slipping for a variety of reasons. Besides the clutch pressure plate and the clutch disk, clutch slipping causes can often be found in the release system. Additional causes include an incorrectly reworked flywheel or installation of the wrong clutch.

Check in case of clutch slipping:

- Release system wear, freedom of movement, adjustment?

- Correct parts for the vehicle?

- Flywheel correctly reworked?

- Contamination of the friction surfaces with lubricant?

- Deformation and warping of the friction surfaces on the flywheel and pressure plate?

Causes of clutch slipping

Cause:

- Normal wear for the specific conditions of use

- Frequent start-up operation / incorrect driving style

- Clutch actuation mechanism stiff

- Actuation system not correctly set or reset

Consequence:

Full downforce not available for clutch pressure plate

Cause:

- Damaged transmission or engine sealing

- Excessive grease on the transmission input shaft or pilot bearing

- Leakage in hydraulic actuation system

- Contamination of the friction surfaces due to incorrect handling

Consequence:

- Clutch slipping due to lower friction values of the facings

Cause:

- Clutch permitted to slip constantly

- Vehicle started up in too high a gear

- Insufficient downforce

- Problems in the release system - no clutch play and consequent stiffness

- Contamination with oil or grease

- Excessive flywheel thickness

Consequence:

- Bonding agent on facing severely deteriorated due to overheating

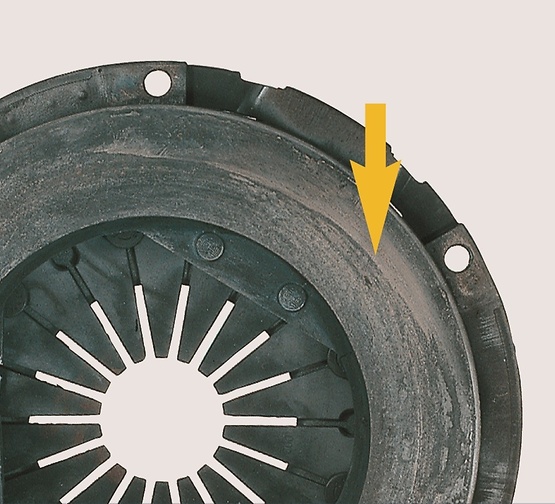

Cause:

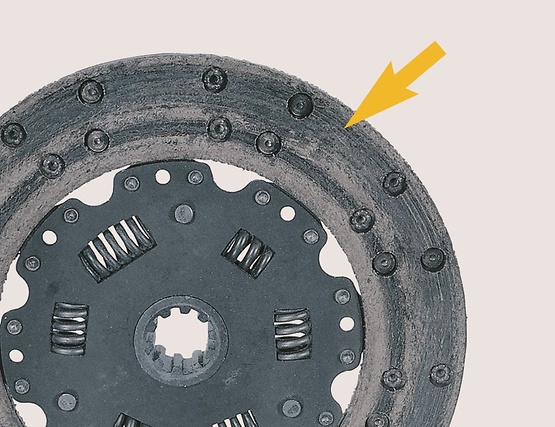

- Friction surface severely scored (flywheel was not remachined)

- Friction surface of flywheel or pressure plate warped due to overheating

Consequence:

- Lower friction values

- Altered friction radius (effective force lever)

Comment:

For new clutch disks, the facing starts off with only peripheral contact (larger friction radius due to minimal dished contact with pressure plate friction surface). As a result, new parts can transmit full power levels even before they are completely run in.

Quality characteristic! No error!

Cause:

- Clutch permitted to slip constantly

- Contamination with oil or grease

- Problems in the release system - no clutch play and consequent stiffness

- Flywheel too thick (remachining not done correctly)

Consequence:

The clutch slips because the downforce is too low. In all cases, the constant clutch slip will generate more heat than can be absorbed. This results in overheating.

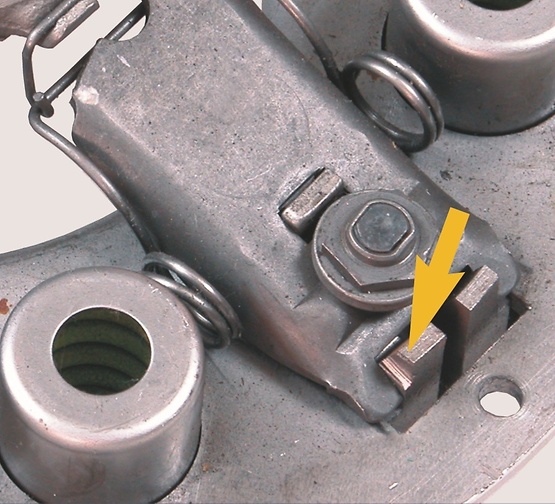

Cause:

- Actuation system worn

- Worn guide tube

Consequence:

The effect of the downforce is negatively affected by the jammed clutch releaser.

Cause:

- Excessive pressure / release travel greatly exceeded

Consequence:

- Diaphragm spring downforce no longer conforms to application design values

Comment:

Also causes drag due to insufficient lift on pressure plate

Cause:

- Continuous or off-center releaser contact on the release ring or release levers

Consequence:

- Clamp force no longer effective because the release levers are blocked by the guide cams when the clutch is engaged

ZF Aftermarket product range

Discover the complete portfolio of clutch systems in our product catalog.