It may not be possible to over-emphasize the importance of proper clutch installation for efficient operations of your vehicles. One of the critical steps in this process is to conduct a proper inspection of the clutch disk before it is fitted. Skipping this step may prove fatal in the future, as it might give way to problems with the clutch plate, pressure plate, or other related complications with the car.

What Does a Clutch Disk Do?

The clutch disk is the central part of the clutch assembly and is responsible for connecting the engine to the transmission. In conjunction with the pressure plate and clutch plate, it transmits engine torque to the transmission’s input shaft. The clutch disk plays a crucial role in reducing engine speed variation, thereby guaranteeing the smooth functioning of the transmission.

Why is Lateral Run-Out Important to Check?

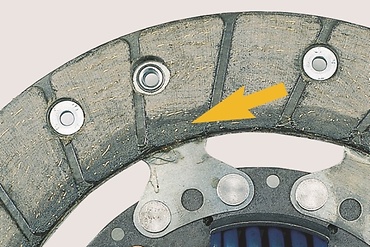

Lateral runout is the term used to describe the movement of the clutch disk as it rotates from side to side. However, if not limited to the recommended range, this wobbling could impact the connection between the clutch plate and pressure plate, therefore you might be compelled to repair or replace your car's clutch sooner than anticipated.

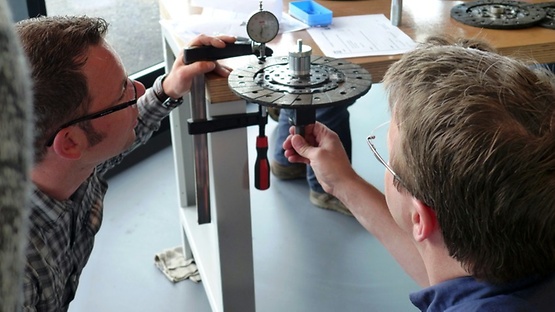

Understanding the SACHS Lateral Run-Out Test

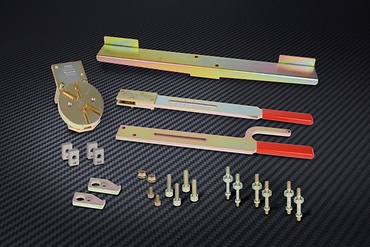

The SACHS lateral run-out test focuses on measuring the eccentricity of a clutch disk so that it can function correctly. This is accomplished by creating an environment in which the clutch disk is sandwiched between two plates where opposite force is applied to see if the clutch disk rotates properly or not. Thus, only clutch disks that undergo this test are authorized for fitment.

Why Lateral Run-Out Must Stay Under 0.5 Millimeters

For proper clutch functioning, the clutch disk's lateral run-out should not be more than 0. 5 millimeters. If this limit is exceeded, the clutch plate cannot disengage effectively, resulting in positive engagement between the engine and the transmission. This may lead to early wear out of the cars and may require car clutch repair.

What Causes Lateral Run-Out in Clutch Disks?

Possible causes of lateral run-out in clutch disks include shock during shipping, improper positioning or storage, and mishandling. Therefore, inspecting each clutch disk before clutch installation is necessary to identify any deviations that could affect performance.

How-to-guide

To avoid clutch problems during installation:

- Clutch disk should always be checked for lateral run-out before installation.'

- In addition, make sure that the pressure plate and the clutch plate are properly positioned.

- As for the clutch disk, make sure that the right equipment is employed to carry out the process.

- Proper scrutiny of the flywheel should be made before the clutch disk and clutch plate is installed.

Following these steps will help you prevent signs of clutch wear and make installation easier

Free Clutch Installation Resources from SACHS

SACHS provides a variety of free informations to assist mechanics and DIY enthusiasts in understanding how to install clutch components correctly. This informations encompass everything from recognizing signs of clutch wear to detailed, step-by-step instructions on clutch installation.

Clutch disk installation is very important in determining the overall functionality of the auto transmission system well into the future. If lateral run-out is a problem on the disk or if it is not within the recommended specifications, you’ll end up with more expensive repairs and your clutch plate may wear out faster than it should.

FAQs

You might notice signs of clutch wear, such as difficulty in shifting gears, a spongy clutch pedal, or slipping during acceleration. If any of these symptoms occur, it's time to inspect the clutch disk.

You can assess the wear of the clutch plate by measuring its thickness and checking for cracks or uneven wear. It is also important to measure the lateral run-out to ensure it falls within the acceptable range.

If you notice unusual noises during operation, have trouble shifting gears, or experience inconsistent clutch engagement, these could be signs of a misaligned clutch. Realigning the pressure plate and clutch plate can often resolve these issues.

When replacing the clutch disk, it's important to resurface the flywheel to ensure smooth contact between the flywheel, clutch plate, and pressure plate. Get it checked to ensure optimal functioning, and only if required replace the flywheel. This step can help prevent future issues with disengagement and prolong the life of your clutch system.

ZF Aftermarket product range

Discover the complete portfolio of clutch systems in our product catalog.