The ongoing development in the automotive industry has resulted in increased requirements for braking systems in vehicles.

The reasons for this are complex. On the one hand, vehicles are becoming ever more powerful and therefore faster, on the other hand – due to the growing number of components for more safety and comfort – they are also becoming heavier. This means that braking systems have to become ever more resistant. Another aspect which cannot be ignored are the modern suspension systems in the vehicles. Although these provide a higher level of comfort and better driving dynamics, they only permit much smaller tolerances for the individual components.

While a vehicle with wishbones on the front axle used to have a tolerance of approximately 100 μm (0.10 mm) for lateral runout, this has been reduced to less than half of this value with modern multi-link suspension.

Beyond the usual wear on a brake disc, the following complaints are conceivable:

- brake judder - thermal judder, cold judder, thickness variation

- judder from stationary marks

- noise

- insufficient braking action

- brake discs showing cracks

- brake discs showing grooves

We want to look at the issue of brake judder in more detail in this article.

Some vehicles tend to be more prone to brake judder due to the high strain on the braking system.

This phenomenon can have multiple causes. It is therefore necessary to carefully check the vehicle as well as the braking system in order to identify the fault and fix it permanently.

A widely accepted misconception is that brake discs have to have a slight runout so the pads can release from the disc again after braking. This is definitely not the case, though.

All brake discs manufactured by TRW are individually calibrated and balanced to prevent uneven weight distribution at higher speeds and to avoid placing additional strain on the suspension.

Juddering refers to rotational vibrations of the steering wheel which occur during braking and are usually accompanied by a booming noise. Depending on their cause, these phenomena are divided into thermal judder, which occurs during deceleration from high speeds, and cold judder, which can occur at any speed.

How-to-guide

Brake disc with material transfer

"Thermal judder" can be described as follows:

- A booming noise in a frequency range between 100 and 250 Hz. The intensity of the booming can vary during deceleration but does not affect braking.

- Vibrations in the steering wheel and a pulsation in the brake pedal.

The intensity of brake judder during braking depends on the currently active brake force (pedal force). The effects of hot judder can usually be identified by a circular arrangement of spots on the friction surfaces of the brake disc. The local temperature peaks during braking result in a transfer of material from the brake pad to the brake disc and/or a permanent change in the structure of the brake disc casting material. Any transferred material is usually removed again during normal braking. Local structural changes – also referred to as martensite formation – are harder than the basic structure of the disc material and can be removed only by machining. When repairing a disc with martensitic spots, it is important to completely remove the hardened areas without reaching or falling short of the minimum thickness of the brake disc. To prevent risks, however, the disc should ideally be replaced.

Brake disc with "hot spots"

In most cases, judder is caused by several factors, making it difficult to clearly identify the root cause. It is therefore necessary to proceed step by step when identifying the cause:

- First determine whether the judder is coming from the front or the rear axle.

- Then check the brake components, starting with the brake pedal and then the brake booster, the master cylinder, the brake lines, the brake hoses up to the wheel brakes. For safety reasons (uneven braking action), brake pads and brake discs, brake drums and brake shoes always have to be replaced in complete axle sets. In addition to this, the wheels should be checked for balance, axial runout, radial runout and condition of the tyre tread.

- Then check axle settings, wheel suspension, steering components and wheel suspensions and adjust or repair these as necessary.

Defect on the wheel suspension

"Cold judder" occurs during normal braking and can be identified by pulsation in the brake pedal, torque fluctuations in the steering wheel and/or vibration of axle and chassis components.

The characteristic differentiating this from "thermal judder" is that cold judder can occur virtually every time the brake is applied, regardless of temperature, and has a much lower frequency range (about 5 to 50 Hz). These noises can be louder or quieter depending on the speed.

The main cause of cold juddering is the thickness variation in the brake discs (see XZS107). Furthermore, defective bearing parts and wheel imbalances can also increase the effect, as with thermal judder.

Reasons for variations in thickness

Radial runout defects due to incorrect fitting cause local contact between pad and disc during every wheel rotation when driving, even without activating the brake. Although the contact forces are relatively low in this case, loss of material (thickness difference) occurs at the respective point on the brake disc, which leads to juddering from a certain magnitude.

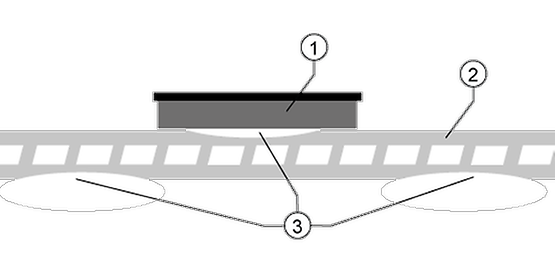

Image: Brake disc with thickness variation (1) Brake pad (2) Brake disc (3) Wear/thickness variation

Factors influencing thickness variation

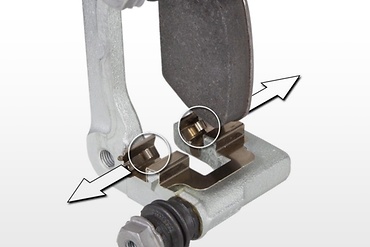

Thickness variations can occur during driving as a result of "washouts" which are caused by partially contacting brake pads. Slightly seized pads or pistons are often the cause.

Other causes are incorrect fitting (dirt, corrosion, excessive torque from impact wrench, etc.), the conditions of use, the driver's driving style and the traffic conditions.

Thickness variations can be generated on long motorway journeys with very light braking, which leads to juddering. On most brake discs, this can be regenerated with a few stronger braking cycles.

The driver will perceive a temperature independent, pulsating brake pedal (cold judder).

The effects of thickness variations can vary greatly from vehicle type to vehicle type and depend on the power transmission factors described and the damping capacity of axle, steering and chassis parts.

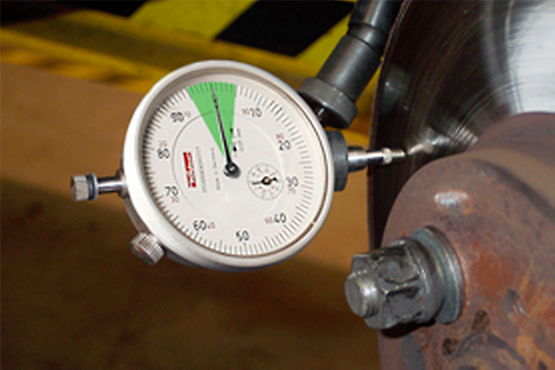

Measuring a brake disc

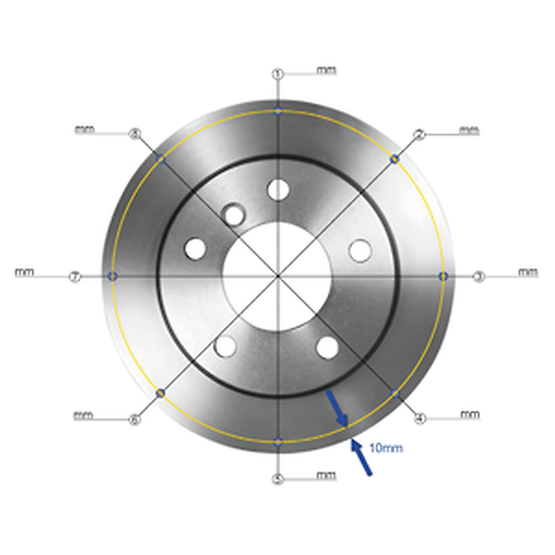

Axial runout of brake discs is checked on the installed brakes and is carried out with a dial gauge (measuring accuracy of at least 0.01 mm) approx. 10-15 mm below the outer disc radius.

The measured value should not exceed 50 μm (0.05 mm) or 100 μm (0.10 mm) on older vehicles, measured over several wheel rotations.

A satisfactory result can be achieved by positioning the brake disc on the hub in relation to the fastening bores in a way that creates the lowest measuring value. If necessary, this has to be optimised through the exchange/combination of influencing components (hub, brake disc, bearing).

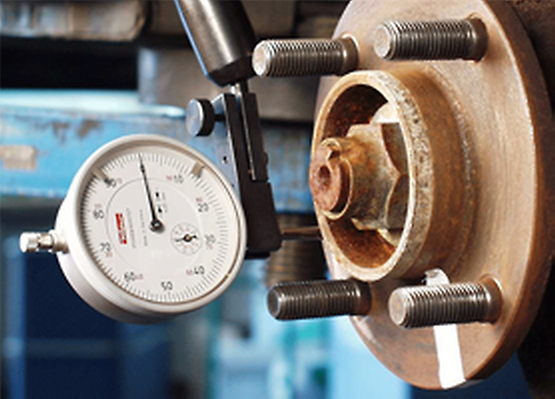

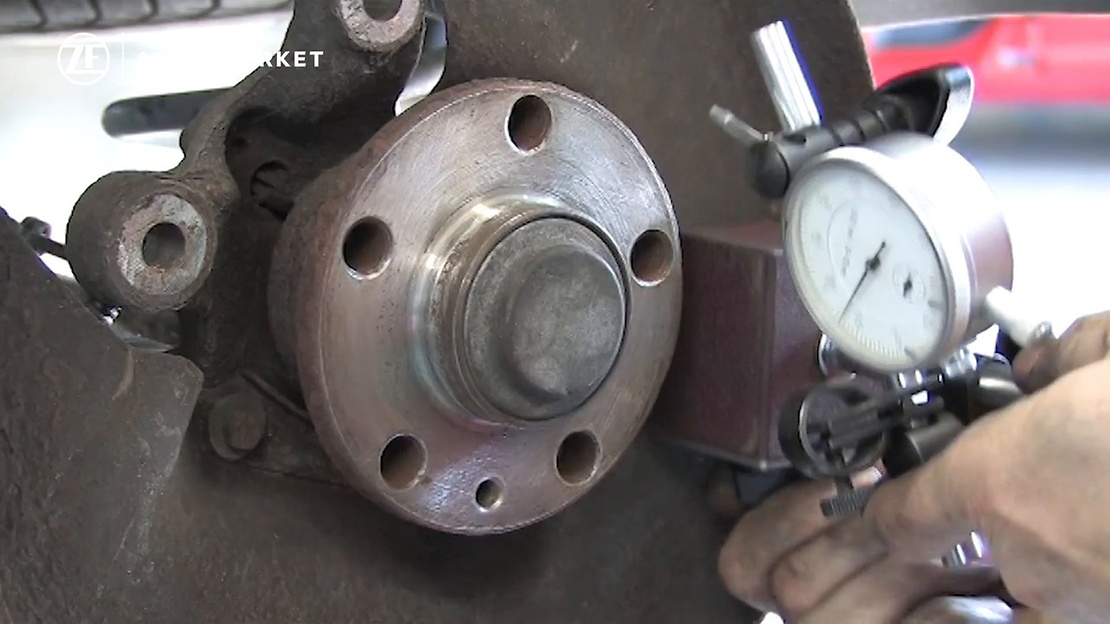

Measuring the wheel hub

Furthermore, exceptional care has to be taken with regard to the clean and flawless condition of the contact surfaces and seats (see XZS103). As mentioned above, the hub may also be responsible for excessive disc runout and has to be measured with reference to the radial runout. In this case, a maximum value of 30 μm (0.03 mm) can be accepted as the reference value; this refers to the measurable outer radius. For larger deviations, the wheel hub/wheel bearing has to be examined and replaced if necessary.

Measuring the thickness variation of a brake disc

In production, the thickness variations of the friction ring on the brake disc can only be measured accurately with special equipment. However, this can also be carried out at the workshop with sufficient accuracy by means of a precision micrometer, which has a measuring accuracy of +/- 0.001 mm. This should be measured on eight points on the circumference at a distance of approx. 10 mm from the outer friction radius. Depending of vehicle type, uneven thicknesses of 12 - 15 μm (0.012 - 0.015 mm) can already lead to juddering. These values therefore must not be exceeded. Service Information XZS107 describes how to calculate the thickness variation.

Wheel hub without visible light gap

Warped and dirty wheel hubs lead to:

- warped brake discs

- brake judder

- brake disc with load on one side only

- uneven temperature distribution

- increased wear of the ball joints and wheel bearings

- risk of wheel bolts coming loose (see XZS103)

Wheel hub with visible light gap

Another test step is to check the contact surface of the wheel hub.

Use a straightedge to quickly and easily check the contact surface of the wheel hub. If a light gap is visible, replace the wheel hub immediately. The brake disc can be installed without worries only if the wheel hub has an even surface.

Excessively greased wheel hub

The same effect occurs if, after replacing the brake discs, too much grease is applied to the wheel hub after cleaning. The brake disc does not rest evenly on the flange and a slight disc runout occurs. This grows over time until the driver notices the symptoms mentioned above.

Furthermore we recommend carrying out a few tests in the same way as described in the "thermal judder" section. This includes the function status of the disc brake, the wheel bearings, the wheel suspension and the steering components as well as front axle adjustment. The information above illustrates that the causes for an excessive radial runout and thereby for the generation of thickness variations are not very easy to detect. Often, only the brake discs and pads are replaced on the affected vehicles, even though measuring the components and possibly replacing them could localise and remove the fault to a great extent.

Nice-to-know

ZF Aftermarket product range

Discover the complete portfolio of brakes in our product catalog.