So is the brake booster defective or is it not? Anyone who has ever carried out fault tracing on the vacuum system of a vehicle knows this question. This practical advice was created to provide support with finding the right diagnosis. The video describes the entire fault tracing procedure using a suitable test device. Additionally, the end of this article contains a link to an interactive PDF file describing additional steps for the final analysis of a fault.

How-to-guide

First a quick test should be used to verify whether there is a fault in the system at all. This is necessary because there are many times when customers complain about a fault because the pedal suddenly feels differently, which could have other causes.

If there actually is a fault in the vacuum system (lack of braking support), the entire vacuum system has to be checked first. If no leak can be found, the non-return valve has to be checked. This can be a quite tricky component. Therefore a brief description of the function first:

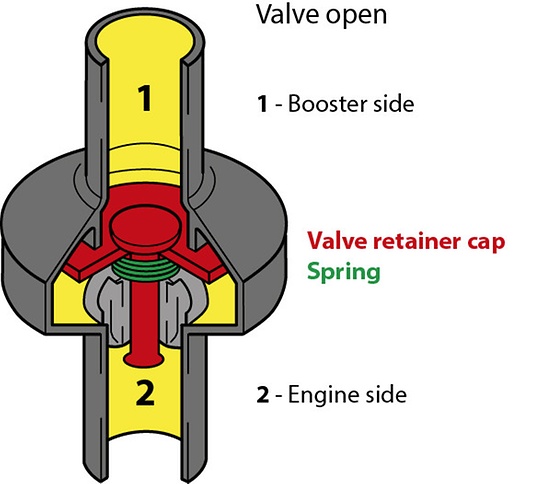

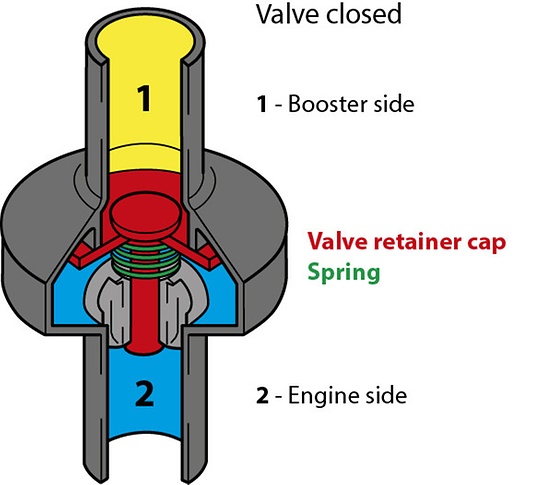

The non-return valve is installed in the line (hose) between the brake booster and the intake manifold or the vacuum pump of the vehicle engine. When the engine is switched off, the valve closes which maintains the vacuum in the brake booster (storage of “vacuum energy”). Additionally the non-return valve prevents fuel and oil fumes from entering the brake booster.

When the engine is running and after operating the brakes, a pressure differential occurs on both sides of the valve which causes it to open – “suction” (purging) starts. As soon as a balance has been reached (same vacuum), the spring closes the valve – the vacuum in the brake booster is maintained at a constant level.

This function description allows deduction of three possible causes for faults:

- 1. If the valve no longer closes due to a stuck valve retainer cap, a rapid loss of vacuum will occur.

- 2. Oil and fuel fumes can enter the brake booster, condense there and destroy its membrane which will result in the total failure of the brake booster.

- 3. If the valve no longer opens due to a stuck valve retainer cap, it is no longer possible to create a vacuum in the brake booster.

All these defects mean that the driver has no braking support and is therefore at risk of an accident!

The interactive PDF – publication number XZT101 – details the complete fault tracing process again.

Nice-to-know

ZF Aftermarket product range

Discover the complete portfolio of brakes in our product catalog.