Contributed by Technical Team D-A-CH

April 18, 2023

4 minutes read

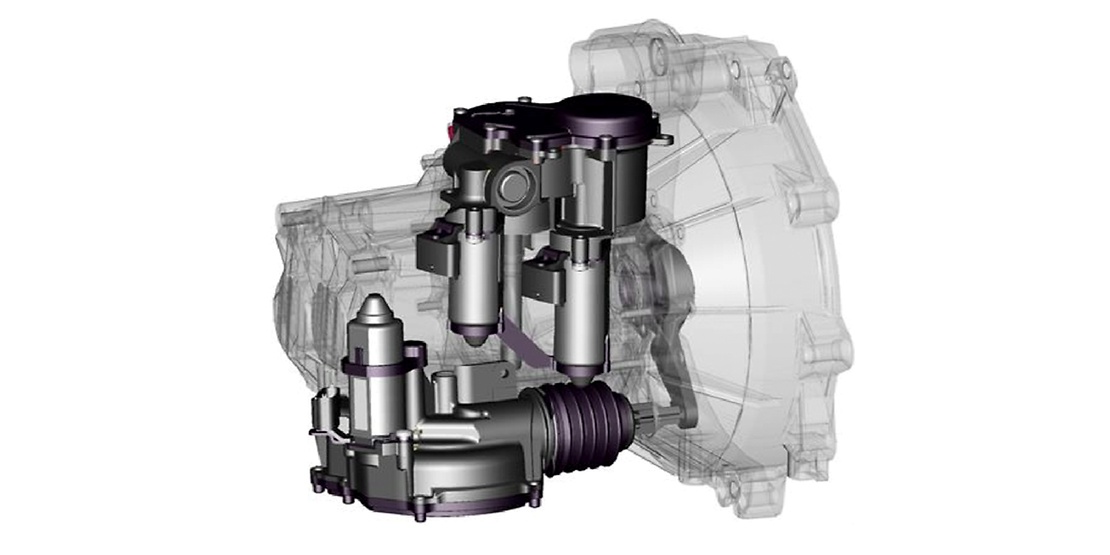

Converting electrical signals into motion - that's the core task of actuators. Depending on the respective function, the actuators take on the role of the clutch pedal or the shift lever. They are used with robotized transmissions (also called guided or automated transmissions) with single or double clutch. As soon as the ESG deems a gear change appropriate, it works on the clutch actuator, the transmission actuator and the engine altogether. However, the driver can still change gears directly using the shift lever or the shift paddles on the steering wheel.

SACHS transmission and clutch actuators in comparison

If you want to find out more about the task, structure and function of SACHS actuators, we have to take a closer look, because we differentiate between transmission control and clutch actuators.

Transmission and clutch actuators from SACHS are similar in structure: both consist of an aluminum housing and plastic teeth. However, in contrast to the clutch actuator, the transmission actuator has two electric motors.

Workshop tips

Finally, we have a few tips for everyone who works with SACHS actuators:

- After installation, actuators must be trained or calibrated with a suitable diagnostic device.

- With Smart models, the clutch actuator must first be correctly positioned using a spring scale or scale, depending on the model. (service info available)

- Activate actuators only when installed using a diagnostic device!

- Do not control actuators by manually energizing them!

About the authors

The Technical Team

Our technical team for Germany, Austria and Switzerland consists of real troubleshooters: When it matters, they are there!

"Always on the technological pulse!"