For a safe and smooth drive, all your car’s components must be in satisfactory condition. Your car’s front end, for example, has several steering components that provide ample manoeuvrability. For these components to operate at an optimal level, they must be in good condition. One of the major considerations is the fact that they may deteriorate with time.

When addressing the important components of your vehicle’s front end, tie rods cannot be overlooked. These crucial rods play a pivotal role in translating your steering inputs into smooth and precise cornering movements. However, tie rods can deteriorate with time, posing a major risk to your vehicle’s steering stability. In this blog, you will learn all about tie rods, their role, signs of them being worn out, and replacement techniques.

If you feel a bump in the steering when driving over road bumps or curbs, this might be due to worn tie rod ends or inner tie rods. Clicking noises during sudden steering movements can also be symptoms of a defective tie rod. In order to determine the exact cause and replace the defective tie rod, the car must be elevated with a vehicle lift in order to be examined more closely.

This useful tip applies to the exchange of tie rod ends and inner tie rods, which together form the so-called tie rod.

Understanding Tie Rods and When Replacement is Needed

To keep your car running smoothly, you must keep an eye out for signs of tie rod wear. Let us first learn what tie rods are and what they do.

What Are Tie Rods and Their Role in Steering?

A tie rod is a vital steering component found in the front end of vehicles such as cars, trucks, SUVs, and Jeeps. This specialised linkage transmits mechanical force to a vehicle's front tyres, allowing for inward and outward rotation. Tie rods are attached to a hub's steering knuckle at one end and the steering rack at the other.

The tie rods on a vehicle also play an important role in determining and maintaining front-end alignment. The "toe," or inward or outward rotation, of a vehicle's front tyres is controlled by adjusting the tie rods on a car or truck. As a result, abnormal or irregular tyre wear is avoided, maximising tread life.

The tie rod in your vehicle’s steering system connects the steering knuckle to the steering rack. It is the key player in the wheel-turning process. When you turn the steering wheel, the entire steering system goes into action, with the rack and pinion system at its core. Either push or pull the wheel, resulting in the precise turning of your wheel.

Signs that Indicate the Need for Tie Rod Replacement

- Uneven tyre wear

- Abnormal noises on the steering

- Vibration in the steering wheel

All of these signs indicate that you get a tie rod replacement. If left unattended, a failed tie rod can cause a loss of control and let the wheel break completely free of the vehicle.

How-to-guide

Note: Cleanliness is extremely important when working on the power steering. Incorrect work and contamination can lead to leakage and, in the worst case, to failure of the steering assistance.

Spraying the fastening nut

- Lift the vehicle and dismount the front axle wheels.

- Spray the fastening nut of the tie rod end with rust remover and leave it on for a few minutes.

Dismounting the underride guard

- Dismount the front underride guard.

Removing the tie rod end

- Loosen the fastening nut from the tie rod and remove it completely.

- Remove the tie rod end from the steeringknuckle using an appropriate ball joint separator.

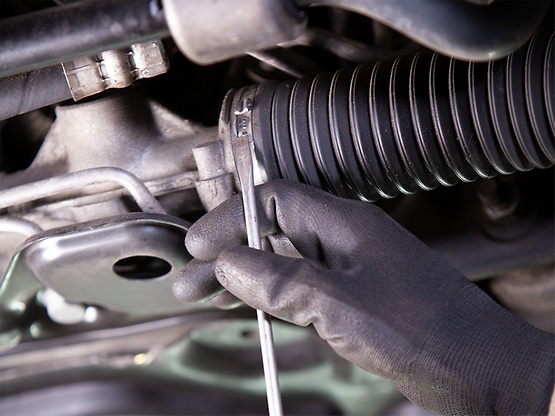

Loosening the clamp

- Remove the clamp of the bellow on the steering gear.

- Push the bellow towards the tie rod end.

Loosening the inner tie rod

- Unscrew the inner tie rod from the rack.

- Clean the sealing face of the bellow at the steering gear.

Cleaning the sealing face

- Clean the lug of the rubber contact surface of the ball joint in the steering knuckle.

- Screw the new inner tie rod into the rack and tighten it with the tightening torque that has been specified by the vehicle manufacturer.

Note: Always use new self-locking nuts and bolts for a reliable repair.

Fastening the clamp

- Mount the bellow and close the clamps with the appropriate special tool.

Note: Incorrect mounting of the bellow can lead to corrosion of the rack: The steering gear starts leaking which can lead to a failure in the steering assistance.

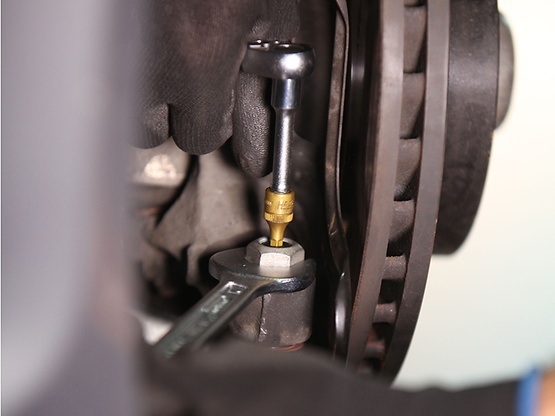

Mounting the tie rod end

- Secure the ball joint in the steering knuckle and mount the nut. Please observe the tightening torque suggested by the vehicle manufacturer.

- Mount the front underride guard.

Note: During mounting, the ball stud should not turn within the ball joint. This can cause damage inside the ball joint and can lead to early failure.

Tip: Secure the ball stud against twisting with a suitable tool!

Mounting the front wheels

- Mount the front wheels and tighten them with the tightening torque recommended by the vehicle manufacturer.

Aligning the wheels

- Align the wheels and adjust them if necessary. Observe the vehicle manufacturer specifications!

- Perform a test drive.

Note: When performing the test drive, pay special attention to the handling while cornering and listen for possible noise emission!

Benefits of Timely Tie Rod Replacement

Timely tie rod replacement can have ample benefits for your vehicle, such as:

Enhanced Steering Control and Stability

It will help increase the steering responsiveness and give you smoother turns with no abnormal noises such as popping or clunking.

Prevention of Uneven Tyre Wear

The tie rods are responsible for your car’s front-end alignment. A faulty tie rod can result in uneven tyre wear; however, you can prevent this with timely replacements.

Expert Mechanic Insights: When to Seek Professional Help

Here are a few car problems that will help you recognise when to seek professional help:

Complex Steering System Issues

Some of the most common steering system problems include:

- Difficulty turning the wheel, especially when your car is at lower speeds or at rest.

- Looseness or less responsiveness of the steering wheel.

- Vibration and shaking of the steering wheel, along with abnormal sounds such as clunking or popping.

Importance of Proper Alignment After Replacement

The tie rods are in charge of controlling the steering angle, while the clamp that connects the outer and inner tie rods aids in steering angle adjustment. This is why, after replacing your vehicle's tie rods, you must perform an alignment test to help reset the steering and suspension to the original specifications of the car. This will ensure that the components perform properly after tie rod replacement.

Conclusion: Steering Towards Safety and Reliability

Your steering should be a breeze to ensure a smooth and safe drive. Any signs of tie rod failure, such as loose steering, vibration while steering, or perhaps even uneven tyre wear and tear, can cause significant damage and expensive repairs. It can also be significantly dangerous for your safety. If you see any such signs, as soon as possible.

ZF Aftermarket product range

Discover the complete portfolio of steering components in our product catalog.