Defective release bearing: specialized knowledge helps prevent damage

A large number of malfunctions in commercial vehicles can be traced to the influence of defective release bearing systems. These malfunctions also include “capital” failures such as burnt-out clutches or poor separating characteristics. As a result, it is extremely important to precisely check the release system. There are not many maintenance jobs where concentrating on a few details can have such a big effect and save major costs. Our workshop tips will help you spot defective release bearing systems by means of a visual inspection.

Defective release bearing systems cause various symptoms. Three examples should serve to explain the types of damage that can result from a faulty release bearing system:

How-to-guide

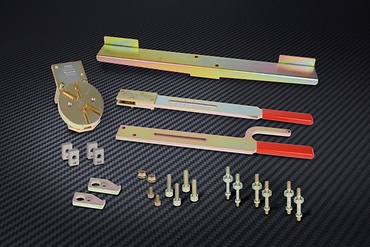

If the bearing points of the guide sleeve (shown in this picture), the release fork, or the release shaft are worn, this compromises the clutch's ease of movement – the worst case scenario is a total failure.

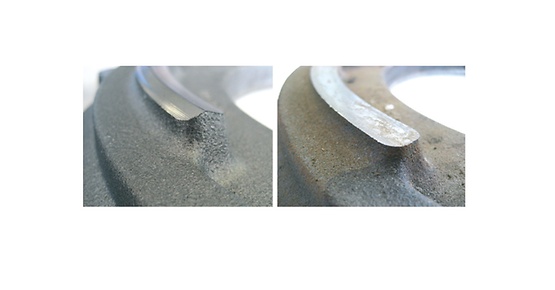

If, as a result of worn components, the release bearing is defective and no longer guided precisely, this also causes an eccentric movement of the diaphragm spring. This, in turn, leads to considerable abrasion in the contact line (pitch) of the pressure plate. The axial position of the diaphragm spring is modified as a consequence and results in an insufficient frictional connection, making the clutch slip.

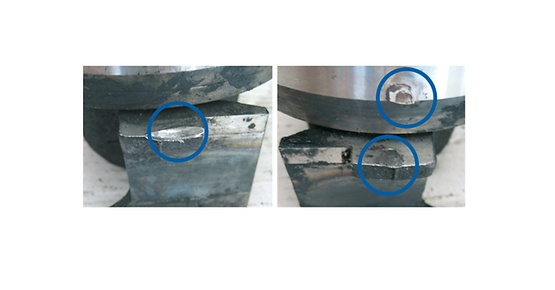

A release bearing which has been incorrectly positioned during assembly may get stuck in the fork. To begin with, this results in a stiff clutch, the release distance becomes shorter and the clutch is not separated properly. The stuck fork cannot transfer the force of the diaphragm spring effectively. After a short runtime, the clutch will also start slipping.

Wear in the release mechanism is one reason for increased pedal force. Particular attention must be paid to the contact surfaces of the release fork, the contact surfaces of the release shaft, and the release fork itself. If these have entered advanced stages of wear (as is shown in the photo with worn guiding sleeve), or are bent, worn or broken, this will have negative consequences on shift performance. Consequences include clutch grab, separating difficulties, or an increasing degree of sluggishness in the clutch. Because there is no load on the release system, manual testing of release shaft operation is not effective. Here a visual inspection makes better sense.

ZF Aftermarket product range

Discover the complete portfolio of clutch systems in our product catalog.