Preventing malfunctions of the clutch actuation system by bleeding it correctly

Even though the electrification of vehicle components is progressing inexorably - the electric power steering system just being one example - especially three components continue to be actuated hydraulically: the brake, the hydraulic or electrohydraulic steering system and the hydraulic clutch actuation system. What all systems have in common is that they need to be free from trapped air in order to function flawlessly.

Air as cause of malfunction

Unlike liquids, air can be compressed. As the aforementioned vehicle systems work according to the hydraulic principle, where power is transmitted by means of a non-compressible liquid column, air is the main cause of malfunctions here. As far as the hydraulic clutch is concerned, the following symptoms may occur:

- Change of the pedal travel

- Difficulties in disengaging the clutch

- Imprecise pedal feel

Hydraulic release systems must therefore be bled according to the vehicle manufacturer’s instructions after clutch repairs or after a replacement of hydraulic components.

How-to-guide

To perform this work quickly and effectively, the relevant workshop equipment must be available. A suitable bleeder is key here. Bleeding the hydraulic clutch components without these devices is tedious and does not always produce the desired results. A collecting vessel for the hydraulic fluid will also be required, with a clear tube that fits on the bleeder nipples. Some bleeders feature a vacuum unit to level the fluid level in the compensating reservoir at the end of the bleeding process.

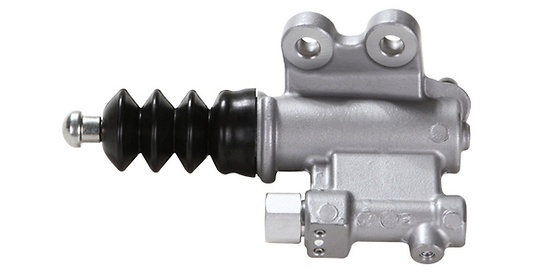

The various clutch actuation systems function on the basis of master and slave cylinder. The master cylinder is actuated by the clutch pedal, the slave cylinder uses the transmitted power to mechanically release the clutch.

The systems differ in the design of their individual components, though. The master cylinders are provided with a separate liquid reservoir, or they are fed by a line from the compensating reservoir.

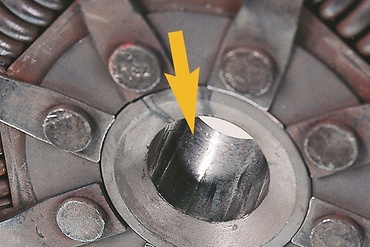

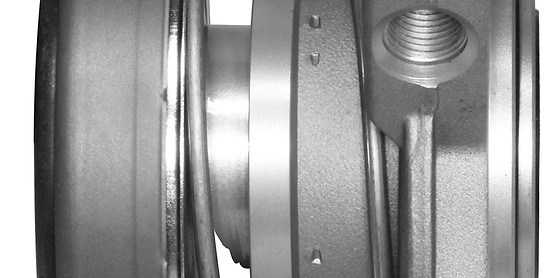

The slave cylinders, on the other hand, are either designed as simple pressure cylinders actuating a lever system to release the clutch or act as concentric slave cylinders directly on the clutch pressure plate. The abbreviation CSC is also used when referring to concentric slave cylinders.

Master cylinder with liquid reservoir

Master cylinder without liquid reservoir

Slave cylinder as simple pressure cylinder

CSC - Concentric slave cylinder

A few fundamental notes on the bleeding process before it is described in individual steps:

- Only use bleeders that have been released by the vehicle manufacturer.

- Make sure that the clutch pedal is retracted all the way to the end position during the bleeding process, so that the flow of the hydraulic liquid is not impeded.

- Keep an eye on the fluid level in the compensating reservoir.

- Keep the bleeding pressure as low as possible. Slow-flowing liquid will transport more air out of the system than fast-flowing liquid.

- Do not operate the clutch pedal during the bleeding process, as this can cause excess travel. The hydraulic cylinder will then be released too far, which can result in leakage.

Only use liquids released by the vehicle manufacturer! Ensure absolute cleanliness when performing the bleeding process!

- Remove filler cap from master cylinder or compensating reservoir and connect bleeder using a suitable adapter.

- Pressurize the hydraulic system (max. 2 bar).

- Remove protective cap from bleeder nipple on slave cylinder.

- Attach suitable collecting vessel with clear tube to bleeder nipple.

- Open bleeder nipple (fixed or twistable).

- Close bleeder nipple again once the liquid in the tube no longer contains air bubbles.

- Release pressure from bleeder.

- Disconnect bleeder adapter from master cylinder or compensating reservoir.

- Check fluid level in compensating reservoir and correct, if necessary (observe MAX mark).

- Place filler cap back on reservoir.

Actuate the clutch pedal several times to perform a function test. The clutch pedal must always independently return to its starting point.

Remove filler cap from compensating reservoir

Slave cylinder with bleeder nipple

Check fluid level in reservoir

Master cylinder with liquid reservoir (right)

ZF Aftermarket product range

Discover the complete portfolio of clutch systems in our product catalog.