The fast and easy way to new brake calipers

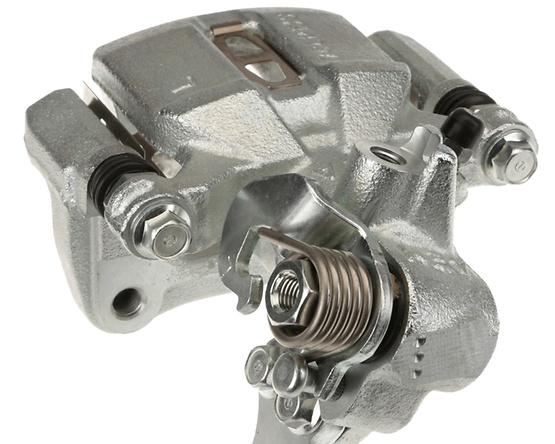

TRW offers pre-filled brake calipers including pre-installed carrier for specific vehicles. This allows the brake calipers to be installed quickly without risk of complaints later on – for example due to worn guide pins.

How-to-guide

If increased wear of brake pads is detected during vehicle servicing or if a customer complains about noise during braking, the reason can usually be found in the area of the brake caliper. Pads stuck in the carrier, worn guide pins (floating caliper) or corroded brake pistons through leaking sleeves can lead to the symptoms mentioned above.

As the subsequently required repair should be carried out at the lowest cost possible to the customer, workshops often only replace the part showing the most obvious fault. This can easily lead to other defective components being overlooked, which also promoted the damage. One example: The housing of a brake caliper shows a corroded, stuck piston. Consequently, the housing is replaced. It may well be, however, that excessive play in the guide pins was overlooked. The problem will appear to have been resolved for a certain period. But then the braking noises will gradually occur again after a while. This will annoy the customer and make them suspicious that the workshop may not have carried out the work correctly. If additional parts, such as the carrier with the guide pins, have to be replaced as well, the customer may refuse to accept any further costs. It is therefore important to take the time for an in-depth diagnosis and to directly replace all defective parts.

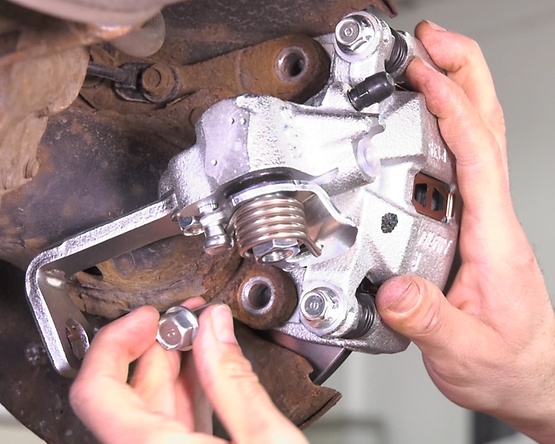

Replacing a caliper including the guide pins offers several benefits here: All wear parts are new and the installation can be carried out faster because no timeconsuming cleaning of the used caliper is necessary. In addition to this, the brake pads can already be installed in the carrier before the caliper is mounted. As the guide pins have to be tightened in a defined sequence and with a specified torque (depending on the system), it is not necessary to obtain the required information in this case.

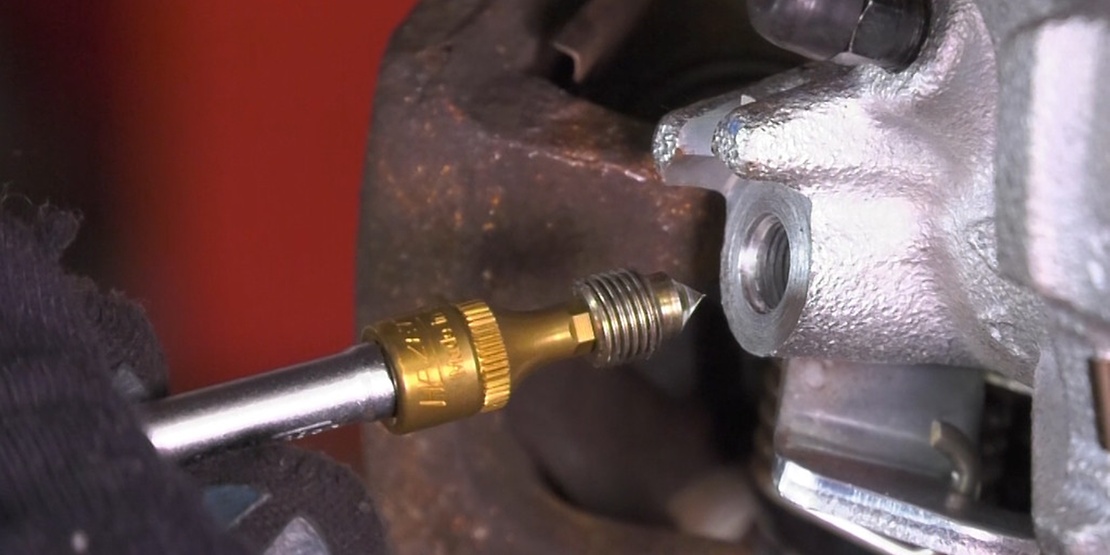

After removing the old caliper, the remanufactured caliper – with the pads already installed – is fastened on the shaft spider with the fastening screws of the carrier. After positioning the previously released handbrake cable and attaching the brake hose, the installation is completed and the brake can be bled.

with parking brake mechanism already being pre-filled. This means the brake is ready to use very quickly after a short bleeding process.

Nice-to-know

Pre-filled brake calipers including installed carriers are a comprehensive repair solution for replacing brake calipers. Fast and easy to repair – a benefit for you and your customers.

More information on pre-filled brake calipers with the corresponding publications can be found in the practical advice “Pre-filled brake calipers from TRW”.

ZF Aftermarket product range

Discover the complete portfolio of brakes in our product catalog.