We previously reported on the advantages of the electric park brake (EPB) from TRW compared to the mechanical versions in "Quality characteristics of electric park brakes (EPB)". This article discusses a problem that only rarely occurs on mechanical versions – when the brake fails to release. The cause for this defect is an interrupted power supply to the electric motors (actuators) which then can no longer release the brake. The exact fault can only be identified by experienced professional mechanics using the appropriate diagnostic tools.

To get the vehicle to the garage, however, it may be necessary to open the brake with the emergency release. Some vehicle manufacturers offer integrated systems for this. The exact handling is described in the operating instructions for the vehicle. For vehicles where this is not the case, we want to describe a general option for emergency release here.

One important note: Do not attempt to release the brake by connecting an external power source. This can destroy the actuator due to different electric controls for the system variants!

To release the brake, you should therefore proceed as follows:

How-to-guide

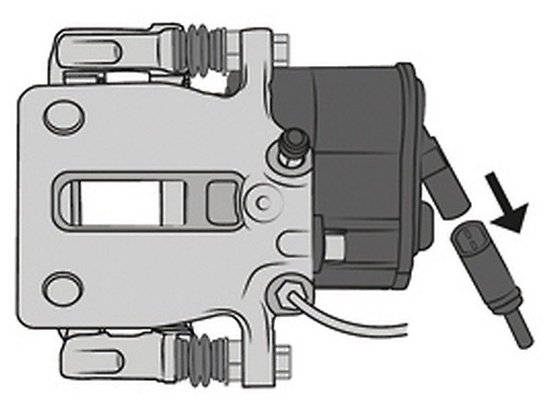

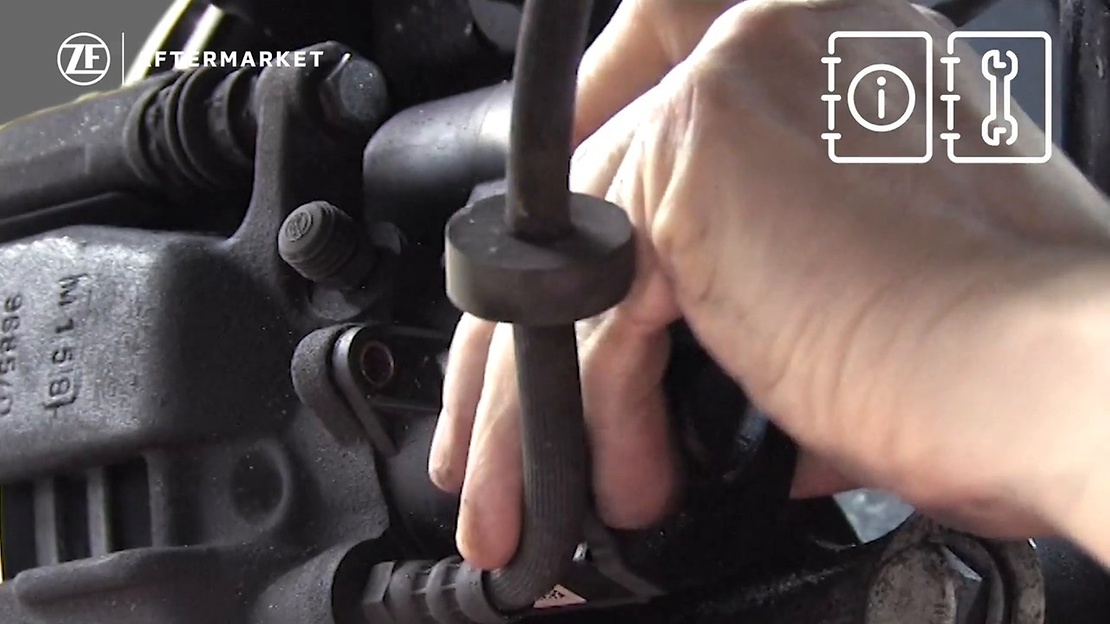

Disengage the connector with a suitable tool and pull the connector from the actuator.

Note: Some EPB systems use actuators with an integrated cable. In this case, the plug connection must be disconnected on the cable harness of the vehicle. This is generally located in the corresponding wheel housing!

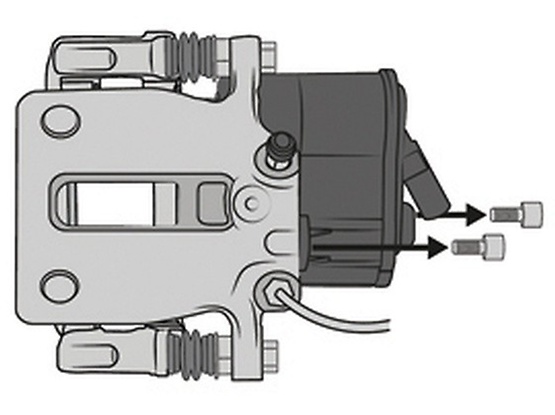

Release and remove both fixing screws of the actuator and any cable holders.

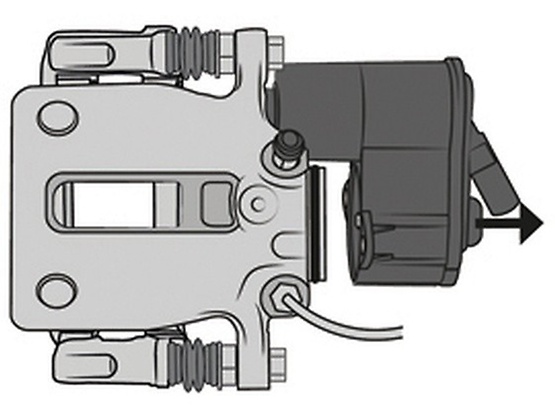

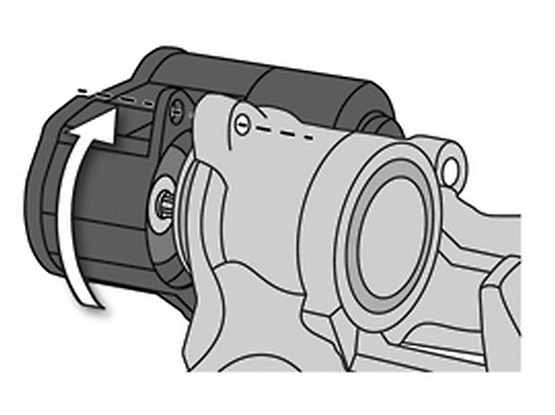

The actuator can now be pulled from the housing in the direction of the arrow.

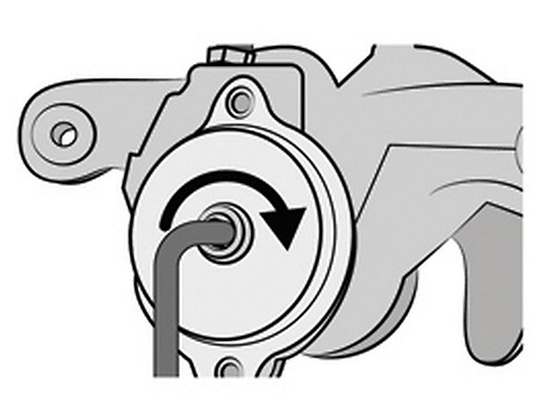

Use a suitable tool to turn the spindle in the direction of the arrow (clockwise) until the brake is free.

- Insert the actuator, ensuring correct seating of the sealing ring.

Note: The motor may have to be rotated slightly during installation so actuator and spindle engage. - Insert the fixing screws

Attention: Ensure to insert and tighten the screws by a few turns by hand. If the thread is damaged, the complete brake caliper has to be replaced! - Tighten the screws with the torque specified by the vehicle manufacturer

- Install the connector

When the brake is fully installed again, the vehicle can be taken to a specialist workshop for further diagnosis.

General instructions for replacing components in the electric park brake can be found at the following link: XZM200.

Nice-to-know

ZF Aftermarket product range

Discover the complete portfolio of brakes in our product catalog.