The Potential of Remanufacturing

The sustainable future means everything for us. Together we can reduce the CO2 emissions, save energy and raw materials. We feel a responsibility to remind ourselves every year of how much of a difference we can make by implementing the right processes and restoring value to quality parts.

With serial remanufacturing of used vehicle parts, up to 90 percent of the raw materials used to manufacture a new part can be saved.

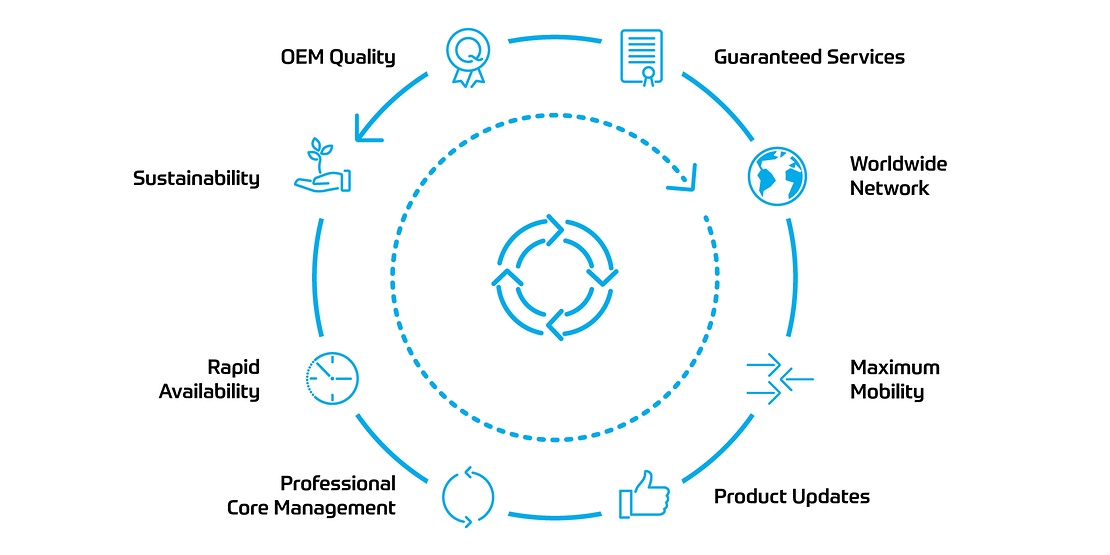

Natural resources are limited, which is why ZF relies on the industrial reprocessing of used parts. The remanufacturing program stands for new mobility and a sustainable future. This is one of the major challenges of the automotive industry. With the remanufacturing program, ZF shows commitment to sustainability and, with its knowledge and innovative strength, takes responsibility for the future.

REMANUFACTURING AT ZF

Value retention with remanufacturing

The world is changing. And, at ZF, we are changing with it. We are pioneering remanufacturing on a global scale, to advance the way the world moves and innovatively reprocessing the materials that move within it.

All our products meet the same quality standards as the original products. We test 100% of the volume and offer a new product warranty to make sure you're protected throughout the product lifecycle. However, remanufactured products are not the same as new products. They are different, but equally valuable.

Benefits for wholesalers:

- Ideal completion of the green product portfolio

- Faster availability of remanufacturing units

- Competent contact point for sought-after parts that are no longer produced

Benefits for workshops:

- No expensive special repair tools

- General damage assessment, no lengthy troubleshooting

- Installation and repair work are simplified

The Diverse Product Range

Remanufacturing products

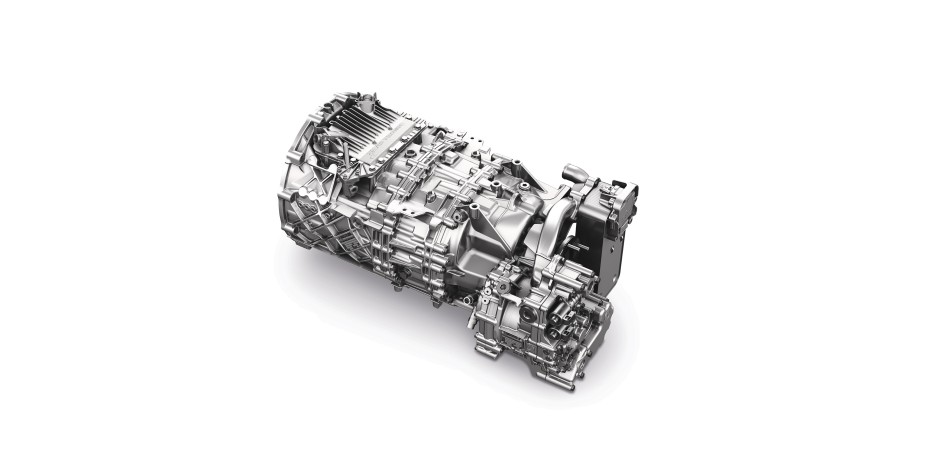

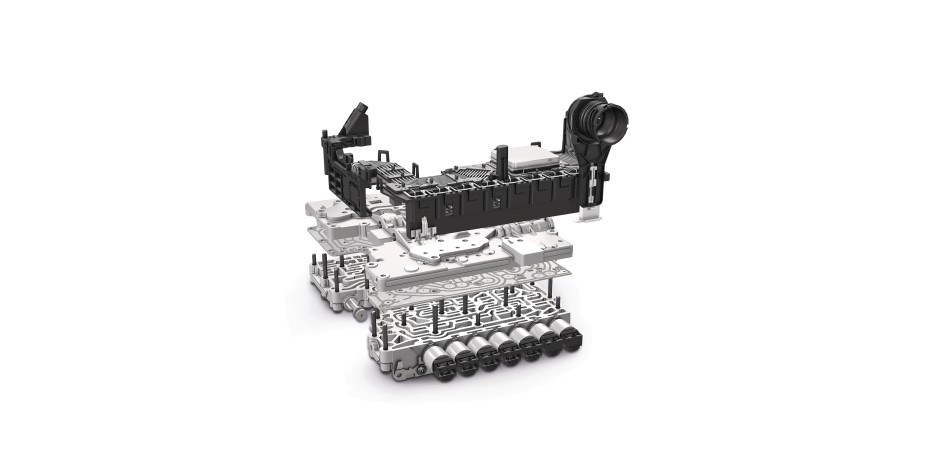

From transmissions to clutches and steering systems to axle systems - ZF offers a wide range of remanufacturing components for cars, commercial vehicles as well as construction and agricultural machinery: