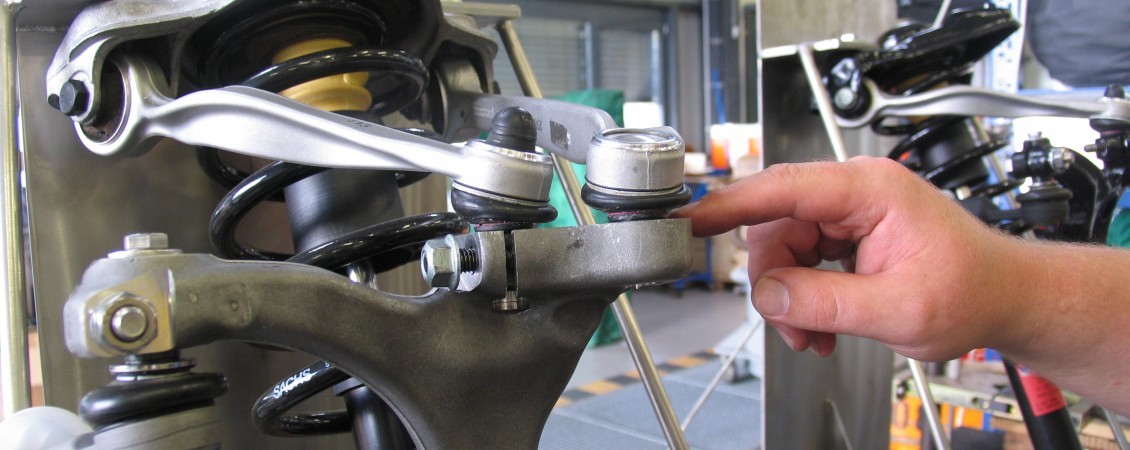

VW Group vehicles belonging to the so-called B5 platform such as the Audi A4, A6, A8, VW Passat, Skoda Superb, Seat Exeo, and others are equipped with four-link suspensions. They are double-wishbone axles that, thanks to the separate link level, improve driving properties significantly. If components are replaced or even just released, the toe-in curve must also be measured and, where necessary, adjusted. The most important feature of the four-link suspension is the higher placement of the steering gear with very short tie rods. Thanks to this design, a defined bump toe-in arises when the axle compresses or rebounds. If the wheel suspension compresses on braking or rebounds on acceleration, the track changes depending on the compression or rebound path. The resulting track values are known as the toe-in curve.

The consequences of an incorrect adjustment

If this is set correctly, the toe-in increases during rebound, i.e. when accelerating, which stabilizes the vehicle. During compression, i.e. when braking, the toe-out increases and the braking performance is supported. If the toe-in curve is set incorrectly, the vehicle breaks away during acceleration and becomes unstable. When braking, the vehicle pulls to one side despite an even braking effect.

VW Group vehicles belonging to the so-called B5 platform such as the Audi A4, A6, A8, VW Passat, Skoda Superb, Seat Exeo, and others are equipped with four-link suspensions. They are double-wishbone axles that, thanks to the separate link level, improve driving properties significantly. If components are replaced or even just released, the toe-in curve must also be measured and, where necessary, adjusted. The most important feature of the four-link suspension is the higher placement of the steering gear with very short tie rods. Thanks to this design, a defined bump toe-in arises when the axle compresses or rebounds. If the wheel suspension compresses on braking or rebounds on acceleration, the track changes depending on the compression or rebound path. The resulting track values are known as the toe-in curve.

The consequences of an incorrect adjustment

If this is set correctly, the toe-in increases during rebound, i.e. when accelerating, which stabilizes the vehicle. During compression, i.e. when braking, the toe-out increases and the braking performance is supported. If the toe-in curve is set incorrectly, the vehicle breaks away during acceleration and becomes unstable. When braking, the vehicle pulls to one side despite an even braking effect.