The most common noises and what they might indicate

Ticking, Clunking, Grumbling?

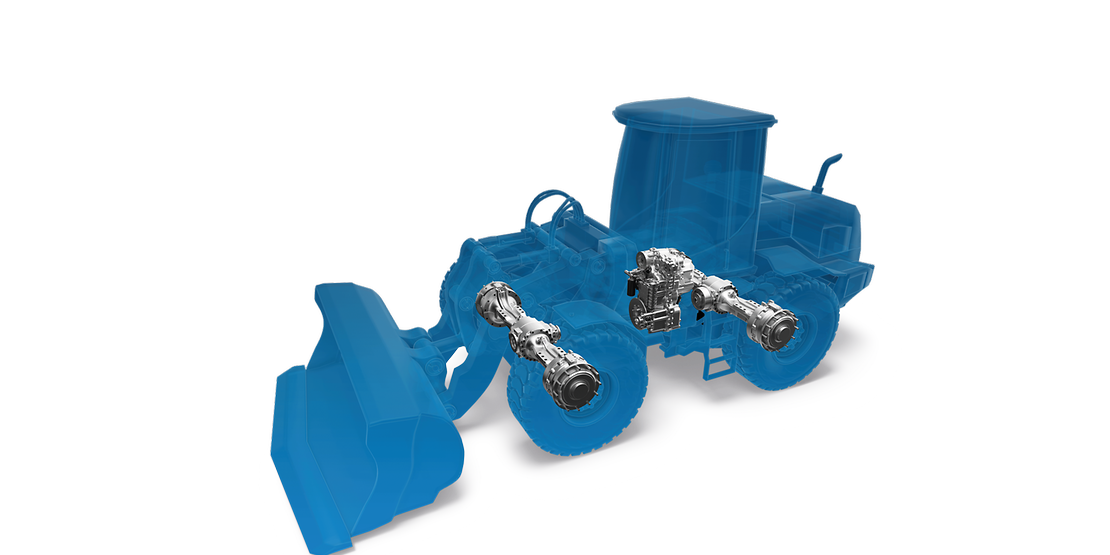

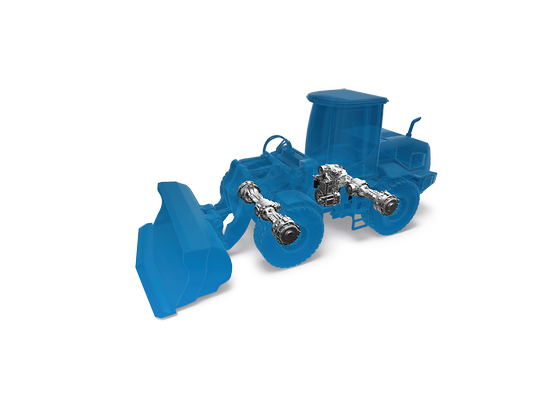

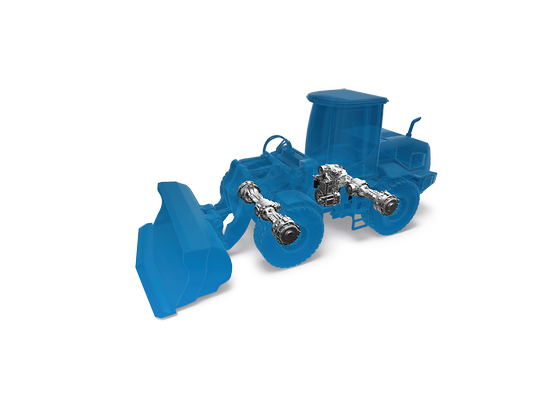

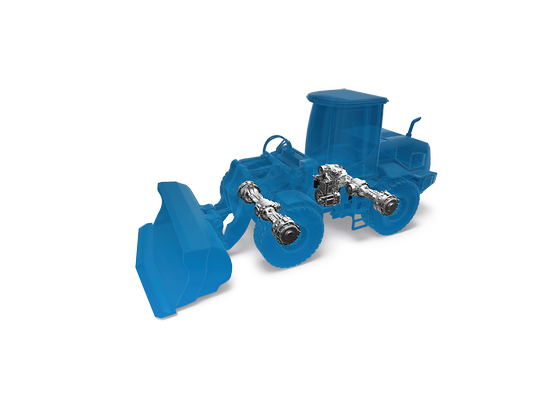

Construction vehicles are subjected to extreme conditions and high workloads on a daily basis. If they break down it is not only costly but has far-reaching consequences on the operational site.

To detect possible problems or malfunctions ZF Aftermarket collected the most common noises and what they might indicate in our Data Noise Bank for construction machinery axles. Ticking, Clunking, Grumbling - simply compare the database sound to the ones of your vehicle and detect what might be the problem.

ZF Aftermarket also offers a wide variety of spare parts and products for construction vehicles tailored to your needs.

Noise selection

Select the noise

Characteristics

- Soft noise

- comes in sequense of several ticks

- not to be heard inside cabin

- can not be felt by driver (no mechanical impact)

Drive situation

- While steering condition

Origin

- While steering condition

Possible root cause

Micro movements between drive shaft and wheel hub bearing, caused by tolerences at spline connection between planetary carrier and drive shaft. No influence to function of lifetime.

What to do?

Axle can be used without limitation

Characteristics

- Short, loud clunk

- only one single clunk

- can be heard and felt inside cabin

Origin

- Wheel hub

- Differential

- Drive line

Drive Situation

Differential lock is activated

Possible root cause

Wheel hub:

Can happen in case of a pressure peak at the brake hydraulic system, means a super elevated acceleration of the brake piston and a consequential hit to the brake disks. Brake hydraulic needs to checked in detail with appropriate electronic measuring devices.

Differential:

In certain situations, the axle differential lock systems are both activated and the whole drive line is back-biased, e.g. while one wheel is in the air and the other three has grip. In such a case there can be clunks from the back-biased driveline, exact point of noise output depending on whole vehicle driveline.

Drive line:

Axle is not properly connected to vehicle frame (screws loose, swivel joint has Play, drive Shaft connection). Axle connection must be checked completely.

What to do?

Wheel hub:

- Go into contact With OEM dealer or give order for assistance to next .

- Provide always sound video (by smartphone) with the complaint.

Differential:

- Check differential lock situation. Make sure that there is no locked differential while steering.

Drive line:

- Check axle connection to vehicle!

Characteristics

- Loud noise

- comes in sequense of several chatters

- can be heard and felt inside cabin

- wheels may judder

Drive situation

Good ground grip for tires

Origin

Differential

Possible root cause

If both axle differential lock systems are working and the whole drive linke is back-biased, e.g. driving small circles on dry ground the disks of the limited slip differential will probably show a slip-stick-effect that can be heard as a chattering noise. The intensity is depending on the iron content of the oil, means increases with contaminated oil. Water contamination of oil has to be checked.

Application check is necessary as for industrial applications as self locking differentials on both axles may could cause the problem.

What to do?

Check general application and if the differential locks works possibly against each other. Take oil samples (ZF number AA02.118.999) and keep them until issue is clarified (0,5 liters). Perform oil maintenance. If problem reoccurs got into contact with OEM dealer or give order for assistance to next . Provide always sound video (by smartphone) with the complaint.

Characteristics

- Loud noise

- high frequency

- not to be heard inside cabin

- can not ne felt by driver (no mechanical impact)

Drive situation

While braking

Origin

Wheel hub

Possible root cause

Indicates worn brake disks unsufficient oil quality in combination with sinter disk brakes. Take oil samples (ZF number AA02.118.999) of 0,5 l each of used and new oil. Disk wear has to be checked. Used oil has to be checked against . Brake hydraulic has to be checked. Water contamination of oil has to be checked.

What to do?

Take oil samples (ZF number AA02.118.999) and keep them until issue is clarified (0,5 liters). Perform oil maintenance. Perform brake disk check acc. instruction. If problem reoccurs go into contact with OEM dealer or give order for assistance to next . Provide always sound video (by smartphone) with the complaint.

Characteristics

- loud noise

- low frequency

- can be heard and felt inside cabin

Drive situation

- While braking

Origin

- Wheel hub

Possible root cause

Indicates worn brake disks or insufficient oil quality in combination with sinter disk brakes. Take oil samples (ZF number AA02.118.999) of 0,5 l each of used and new oil. Disk wear has to be checked. Used oil has to be checked against . Brake hydraulic has to be checked. Water contamination of oil has to be checked.

What to do?

Take oil samples (ZF number AA02.118.999) and keep them until issue is clarified (0,5 liters). Perform oil maintenance. Perform brake disk check acc. instruction. If problem reoccurs go into contact with OEM dealer or give order for assistance to next . Provide always sound video (by smartphone) with the complaint.

Characteristics

- middle noise loudness

- can be heard and felt inside cabin

Origin

- Drive shaft

Possible root cause

Drive shaft is not properly connected (support bearing, joint connection) or is not according specs (e.g. damaged by external impact). Drive shaft has to be checked completely. Depending on the vehicle configuration the park brake may be subject to check also.

What to do?

Check drive shaft status and its connection to transmission and axles.

If failure can not be defined go into contact with OEM dealer.

Characteristics

- persistent noise when driving in circles

- only occurs after several circles

Driving situation

- Driving in circles

Origin

- Self-locking differential with 45% locking value

Possible root causes

Axles become distorted when driving in circles with a high locking value.

Noise has no effect on the service life of the components or on the function of the axle.

Noise is only present when the axles are new and decreases or disappears completely with a corresponding running-in period.

What to do?

Axle can be operated without restriction, no measures necessary.

You need additional support?

Please find the service information for noise problems.

Any other questions?