ZF Aftermarket product portfolio

ZF Aftermarket supplies a full range of parts for a vibration-free drive, including dampers, suspension struts and suspension-strut inserts for virtually any model of commercial vehicle.

We promise to provide excellent, high strength performance as well as improved efficiency to all commercial vehicles.

Every product is produced to match the stringent original equipment (OE) specifications. With our Independent Aftermarket range, you can fit a selection of truck, trailer and bus suspension parts to produce industry-leading performances.

Click here to download our flyer for more information.

The Sachs product portfolio

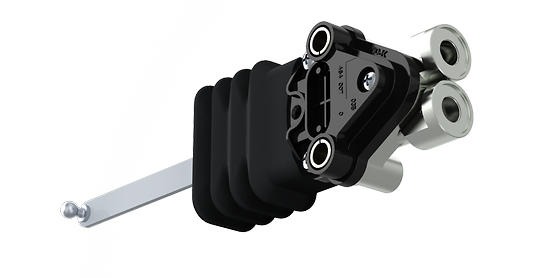

Truck Dampers

SACHS dampers ensure the reliable and cost-efficient operation of trucks and other commercial vehicles. Like all SACHS spares, they are synonymous with German quality and are especially durable. SACHS dampers for trucks optimize driving comfort and effectively relieve the strain on both vehicle and driver. At the same time, they safely transport even the most sensitive payloads.

A damper is a safety-related component which, together with the spring, forms the end link between the suspension and the vehicle body. It reduces vibration in the suspension spring, slows it down and optimizes road contact.

In addition to conventional dampers for trucks, the SACHS portfolio includes driver’s cabin dampers and axle dampers for trailers. One particularly special innovation is SACHS Continuous Damping Control (CDC) for trucks. This is a variable system which adjusts damping intensity in real time based on the driving situation.

As a rule, commercial vehicle dampers should be inspected and, if required, replaced after no more than 250,000 km. In the process, it’s also a good idea to have an expert check the surrounding components. Early identification of potentially defective components near the dampers prevents costly downtime.

CDC Dampers

SACHS CDC (Continuous Damping Control) is the variable damping system for commercial vehicles. With conventional dampers, the damping characteristic curve is set at the factory and cannot be changed. With SACHS CV CDC dampers, on the other hand, electronically adjustable dampers adjust the damping force on all four wheels in real time to the respective driving situation.

Truck CDC dampers offer numerous advantages: they make driving more controllable, more convenient, more relaxed – and feature more safety.

Continuous Damping Control is one of SACHS’ most successful products. Since ZF began to develop this continuously adjustable chassis control system for volume production in 1994 – as the first company to do so – more than 18 million CV CDC dampers have rolled off the belt.

Thought to be an optional system solution for luxury and super-class cars at the time, today, alongside SACHS Continuous Damping Control for passenger cars, there are also bus and truck CDC dampers. Thus, the Continuous Damping Control technology also contributes to the comfort of drivers and passengers in commercial vehicles and protects the payload.

The Continuous Damping Control's operating principle is as intelligent as it is convincing. The design of CDC incorporates an electronically controlled proportional damping valve. During the trip, sensors monitor all influences, such as road condition, current payload or driver actions and report the behavior of the spring elements to the on-board electronics. Thanks to the CDC dampers’ configuration, the control software analyzes the driving situation and calculates the damping force ideal for the present situation within milliseconds. The proportional valve controls the flow of oil inside the damper so that the damping force is is adjusted to firm or comfortably soft. In this way the electronic damping system of Continuous Damping Control ensures optimal comfort and constant safety.

Bus Dampers

Shocks play an essential role in ensuring the safety of vehicles and occupants. In addition, dampers for buses need to meet complex requirements, ranging from changing payload weights to different types of routes and from freeways and heavy city traffic to steep serpentines.

In all of these conditions, SACHS shock absorbers for buses ensure optimum road contact, guaranteeing stable cornering, perfect maneuverability, effective braking performance and extreme durability.

SACHS bus shock absorbers are high-quality spare parts which guarantee optimum damping on all routes. Together with the spring, they form the link between the steering knuckle and the body. While the suspension springs compensate for unevenness in the road, shock absorbers reduce the vibrations of the suspension springs, slowing them down – thus successfully ensuring vital contact with the road.

No matter what kind of bus it is – city bus or coach, simple bus or articulated bus – the chassis needs to provide maximum performance. As a classic commercial vehicle, buses need to operate not only reliably but also economically. This is why SACHS bus shock absorbers were designed for exceptional durability.

The TRW Product Portfolio

Shock Absorbers

Through our TRW range we can offer you a huge selection of shock absorbers for your commercial vehicle customers, allowing you to make a real difference to the performance, efficiency and safety of their vehicles. We have developed a truly exceptional reputation for producing innovative, tailored and advanced shock absorbers, capable of meeting a wide variety of driving requirements.

TRW shock absorbers provide the following benefits:

- Super- reliable valves system for better performance

- A 20% smoother piston rod surface for reduced friction and longer life

- Metal discs within the piston valve resulting in quicker response times

- The most advanced testing process to meet Original Equipment specifications

- Our truck shocks and bus shocks meet the very stringent standards of Original Equipment, meaning you can be assured that choosing TRW will allow you to provide businesses with real benefits to their on-road performance.

Shock absorbers are exceptionally important for the performance of commercial vehicles and if they are not functioning properly then it could lead to problems with handling, braking, efficiency and safety. That is why it is always important to replace faulty or worn shocks before they become a serious issue.

As a OES supplier, we work directly with vehicle manufacturers to ensure that we’re providing parts that match the exact requirements of drivers and fleet owners. We also aim to be first to the market with all of our new products, keeping you ahead of the curve when it comes to improving safety.

With more than 4,000 designers, engineers and technicians working across the world in more than 25 countries, we have a huge network to call upon when we need to develop and improve our parts offering. As a result TRW is responsible for the most advanced shock absorbers in the business. Our newest technical innovations include:

- Valves and strong valve retainers that deliver a more reliable performance with less damage likely during extreme conditions

- The rod of the shock is hardened first before being polished, which provides a 20% smoother surface and helps the seal to be permanently lubricated. This all translates into a reduction in friction which helps to increase the longevity of TRW shock absorbers compared to other parts on the market

- Metal discs within the piston valve are calibrated to 0.01mm, which ensures a much better performance than traditional helical springs. The result is a quicker response time – boosting performance figures, safety features and ride comfort.

All TRW parts are produced to perform above and beyond what is expected of them. To enable us to do this we carry out complete testing on all commercial vehicle parts, which means they can withstand all situations and environments.

To make sure they meet the stringent requirements of the Original Equipment, our bus shock absorbers and truck shock absorbers are tested to the extreme both in the lab and on the road. We don’t send parts to the market unless they pass our gruelling and rigorous tests, which include testing on some of the roughest roads in Africa as well as the coldest environments in Europe. We test to ensure:

- Acoustic comfort for drivers and passengers

- Excellent durability through strength testing

- Leak-free performance with dynamic testing

- On-road ability through track testing

- Ability on bumpy roads with a uniquely designed push/pull out elasticity test

You will get everything that you need for a fast, easy fit when you choose TRW shock absorbers, including full fitting instructions and accessory kits if required. With a full catalogue of products available to view online you can also easily find the specific parts that you’re looking for.

TRW is a name and product that you can trust whenever you need us. Our parts have a proven history of success, which means you can rely on our expertise when it comes to shock absorbers for commercial vehicles. For more information about our selection of shock absorbers, browse the online catalogue today.

The Wabco Product Portfolio

OptiRide™ Electronically Controlled Air Suspension (ECAS)

The global market leading solution in air suspension

Features and innovation

- Electronic control of full or partial air suspension systems

- Flexible ECU concept: cab or frame mounted ECUs available

- Active height sensor detecting precise movements

- Solenoid valves with plastic body to reduce weight and helps to increase component life

- Operated via mobile device, remote control unit and customizable dashboard switches

- Options for retrofit available

- Providing a wide range of value adding features

- See a full list of OptiRide Key Functions

Customer value

- Rapid traction increase via load transfer function saves time and helps to reduce tire wear

- High traction performance enables transition from 6x4 to 6x2 configurations

- Automatic lift axle control reduces tire wear and fuel consumption

- Depending on applications, OptiRide enables fuel savings of up to 3 to 5%

- Fast lifting and lowering for quick and easy loading and coupling processes

- Axle load monitoring with axle load display and automatic driver warning to avoid vehicle overload

- Optimizes damper performance with optional Electronic Shock Absorber Control (ESAC)

Difference

- World market leader with over 2 million systems in use.

- One of the fastest reacting and most robust ECAS solution on the market

- Recognized by 2 CV industry awards in 2013: “HDT Top 20 Products of 2013” as well as the “TWNA Technical Achievement Award 2012”

- Worldwide application support for both 24V 12V systems

Damage Evaluation

Although a damper may appear to have a leak, this may not in fact be the case. A certain amount of "perspiration" is normal, and even necessary to lubricate the piston rod seal. Never assess the damper after driving in the rain; the dampers should be dry.

Noise during spring compression does not necessarily come from defective dampers.

Therefore, check:

- axle suspension

- stabilizer rubbers

- caps

- and, of course, check whether the noise is caused by objects in the load compartment.

Cause:

- Normal wear due to high mileage.

- Wear due to sand (abrasive effect).

- Wear due to driving with ride height too high or incorrectly adjusted air spring level setting.

Consequence:

- Noises (rattling, knocking)

Cause:

- Insufficient tightening torque.

Consequence:

- Play between bush and thread crests.

If the damper is damaged, this was caused by force – through an accident or an installation error.

Therefore, check:

- Damage on axles and damper anchorage

- Perform wheel alignment.

Defective dampers lead to faster wear of adjacent components. Therefore, inspect the suspension strut mounts, service kits, and suspension springs during each damper check. When replacing the damper, also replace the suspension strut mounts and service kits.

In case of twin-tube dampers, air can enter the working space when transported or stored in horizontal position. The air can be easily and effectively removed by compressing and stretching the damper several times in succession. However, the damper independently vents the air shortly after its installation.

When securing the damper (stud joints/suspension strut mounts), please pay attention to the correct alignment of the parts. Check the damper anchorage, steering parts and rubber-to-metal components during each inspection. In this context, it is advisable to slightly grease the mounting bolts of ring joints. Caution: Protect rubber-to-metal components from grease!

Underbody protection and dirt from the road sticking to the damper are often wrongly diagnosed as leakage.

![ZF [pro]Academy ZF [pro]Academy](/media/master/service-images/zfa_pc_training_img_clutch-centering-tool-01_wxh_cmyk_2017-11_un-progressive_bs_32_xl_4.jpeg?v=1125971310)