Let Data Drive Your Decisions

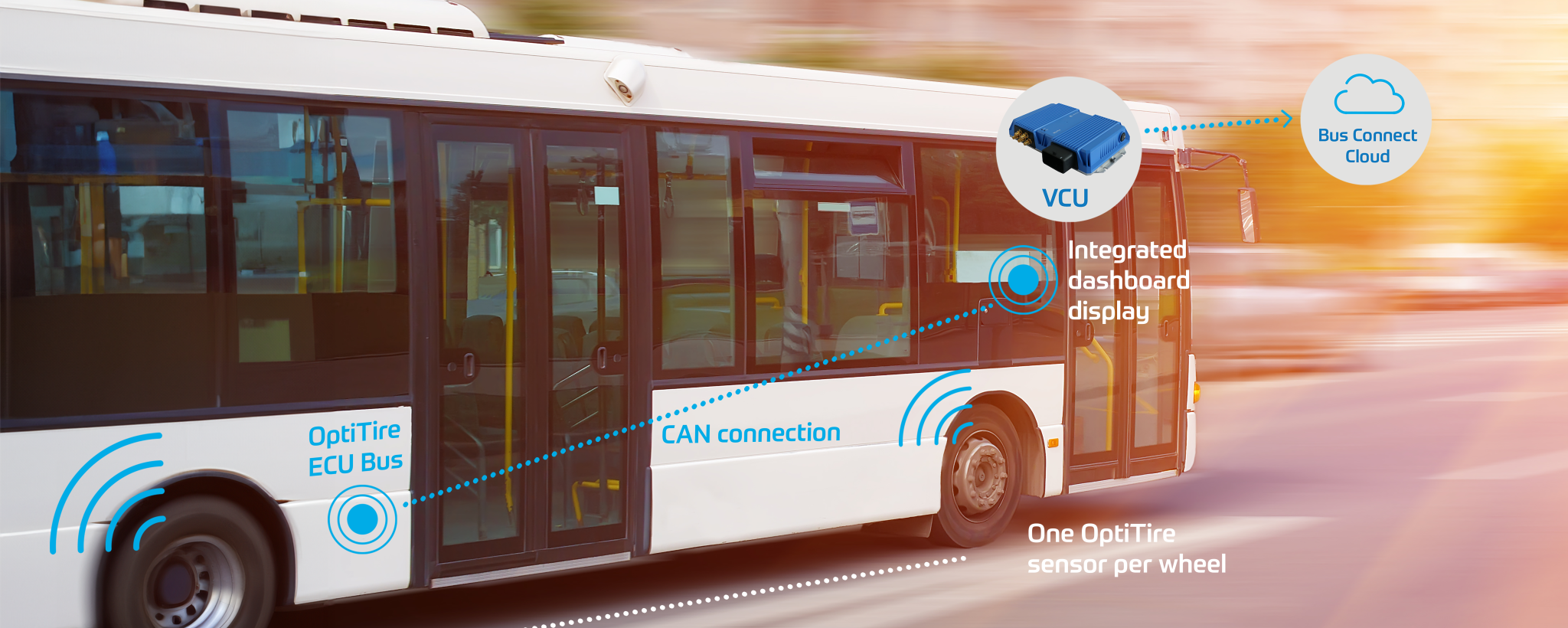

All bus operations from manufacturing and fleet management to servicing can be complex and challenging. That’s why we developed ZF Bus Connect, digital solution that transforms data into insights. A solution for cost reduction, improved safety and increased uptime.

Smart telematics systems are now the best way of managing a fleet. For you as a bus operator, they open up a wide range of new possibilities. Revolutionize your fleet with ZF Bus Connect – vehicle telematics with flexible product packages and extensive integration options. These telematics functions specially developed for buses provide you with an ideal overview in real time. Make your work processes more efficient and benefit from our anticipatory telematics systems for buses and hybrid and electric fleets.

Telematics systems: Advantages for every bus company

Company cost-effectiveness depends on many factors. As a provider of telematics systems, we at ZF can help you to boost efficiency. Telematics in your buses helps make the daily workflows of your entire fleet more transparent, enabling you to respond quickly and specifically to particular situations where necessary. The ZF Bus Connect telematics solution enables you to deploy valuable resources sustainably:

- for simpler workflows in vehicle management

- for better scheduling and/or coordination

- for perfect cooperation between departments

Useful to know: Telematics like ZF Bus Connect also provides detailed reports on route planning analysis and driving behavior as well as on the current maintenance condition. So you can tailor training to your drivers and avoid unexpected downtimes and waiting times in the workshop. Benefit also from our tailor-made Service for buses. Here, ZF offers you cross-product competencies for the maintenance and customized repair of your vehicles.

Discover the Future of Bus Connectivity with ZF Bus Connect!

Get ready to embark on a journey with ZF, where innovation meets efficiency and sustainability. Our latest video introduces you to three remarkable partners who have chosen ZF Bus Connect to revolutionize their connectivity experience.

Are you keen to learn more? Try out our demo.

What our telematics systems offer

Digitalization as a success driver is now found in all areas of telematics for buses. In the commercial vehicle sector, we at ZF have developed a variety of functions, which not only support standard applications such as tracking or displaying maintenance services. They also provide you with substantial benefits as a user. ZF's bus telematics represents a quantum leap forward by networking your vehicle data and generating a more complex data volume to improve your company processes. Leverage the following expertise when using the ZF telematics system:

Modern fleet management with ZF Bus Connect

Cost control is a key factor for any company, allowing them to report the efficiency of their used resources. Access to vehicle-related data such as fuel consumption or the analysis of driver behavior are equally relevant. The ZF Bus Connect system helps you boost savings potential by consistently recording fuel consumption, for instance.

ZF telematics service portfolio for buses

Relevant vehicle data underpin your decisions and optimization processes in the company. Thanks to specific ZF Bus Connect solutions, you can use automatic evaluations and analyses as the actual basis for cost-efficient management. To control costs, you need to understand how they are generated. Leverage the strengths of our system modules:

- They optimize your operation and all processes

- Their integration capability speaks for itself

- The fuel consumption of fleet vehicles can be reduced significantly

- They are compatible with the requirements of electric and hybrid buses

- Worldwide presence

- Ideal expertise for mixed fleets

- Preventive remote vehicle inspection

- Increased passenger safety

- Flexible data connection for logging and transferring data

- Area-based speed monitoring

- Extended evaluation of driving style

Take a look at the portal with its added value

Telematics for buses offers an incredible range of benefits. Documentation of journeys, wide-ranging proof of compliance as well as associated timetable optimizations speak for themselves – all these digital functions underpin quality assurance in your company.

Intelligent control courtesy of the ZF Bus Connect Dashboard

We go the extra mile to make sure our graphical user interfaces provide clear information. Our dashboard includes lots of functions, such as "Live View", "Consumption Monitor", "Vehicle Inspector" and much more. Click on our portal and learn more about the different application options of the ZF telematics bus systems. Standout features include map displays, location portal and the security of a state-of-the-art data protection concept.

Any time, anywhere, access to you fleet on your mobile device - mobile app

Check your fleet any time anywhere on your mobile device with ZF Bus Connect Mobile. All your assets locations in real time, the trip history and more. ZF Bus Connect Mobile will add value to any fleet manager: It provides live insight on the assets locations on the map, tell-tale, fuel or battery charge status and more. Our E-Logbook provides route statistics, history of all individual routes, daily summaries, resting/parking times and more. It is only available for Bus Connect registered customers with an active account.

Fleet management solutions as an investment in the future

Digital system solutions for safe and efficient fleet management require upfront investment. But they will pay for themselves in a few months because the potential calculated savings quickly offset any outlay. And in future your savings will be reflected in your profits. With our wide-ranging portfolio, we are always a strong partner for you. Our knowledge and experience result in solutions that make you even more successful.

Already have the account?

Click below to enter your personal login area.

Not registered yet? Easily contact us here and learn all about what ZF Bus Connect can do for your fleet.

Choose the right solution now

Whatever kind of fleet you operate, ZF Bus Connect can help you fine-tune it. Our tried-and-tested digital solutions measure parameters such as acceleration intensity, the number of braking maneuvers or even cornering speeds. Check the following ZF product solutions and their functional strength:

Check ROI for your fleet

Calculate the expected profit our digital solutions could bring into your fleet via the return of investment calculator below. Just fill your email address.

UPCOMING INTERNATIONAL EVENTS

Come meet us at one of our numerous events and trade show appearances. The list of events in 2024 is below.

| Event name | City | Country | Beginning | End |

|---|---|---|---|---|

| HDAW | Grapevine /Texas | USA | 22.01.2024 | 25.01.2024 |

| ElekBu | Berlin | Germany | 06.03.2024 | 07.03.2024 |

| Bus2Bus | Berlin | Germany | 24.04.2024 | 25.04.2024 |

| Next Mobility Expo | Milano | Italy | 08.05.2024 | 10.05.2024 |

| IT Trans | Karlsruhe | Germany | 14.05.2024 | 16.05.2024 |

| Busworld | Istanbul | Turkey | 29.05.2024 | 31.05.2024 |

| IAA Transportation | Hannover | Germany | 17.09.2024 | 22.09.2024 |

| National Bus and Coach Show | Brisbane | Australia | 18.09.2024 | 19.09.2024 |

| Australasia Bus and Coach | Melbourne | Australia | 01.10.2024 | 02.10.2024 |

| Transexpo | Kielce | Poland | 16.10.2024 | 18.10.2024 |

| FIAA | Madrid | Spain | 22.10.2024 | 25.10.2024 |

| CzechBus | Prague | Czech Republic | 20.11.2024 | 22.11.2024 |

| Eurobus | Birmingham | United Kingdom | 12.11.2024 | 14.11.2024 |

| Intermobility and Bus Expo | Rimini | Italy | 19.11.2024 | 21.11.2024 |