German precision - world-renowned

LEMFÖRDER is the No.1 brand in original equipment steering and chassis components. As a trusted partner of over 50 vehicle manufacturers worldwide LEMFÖRDER is a leader in the development of innovative passenger car, motorcycle, HCV and off-road chassis technology.

For over 70 years LEMFÖRDER has been known for its pioneering spirit and passion for detail – setting the highest standards in steering and suspension.

Founded in Lemförde near Bremen, LEMFÖRDER still engineers over 90% of its parts in Germany. As part of a global organization, LEMFÖRDER follows the footprints of the automotive industry and has production and engineering sites all over the world. Each LEMFÖRDER part is rigorously tested before entering the market.

LEMFÖRDER German engineering

Welcome to Germany, where our pride in precision was born. Discover why LEMFÖRDER means quality without compromise and how every part made by LEMFÖRDER around the world is made with the same German values, attitude and minute attention to detail.

History of LEMFÖRDER

A history of precision

Founded in 1947, the brand was named after its hometown of Lemförde in Germany. The traditional group of companies consisting of Lemförder Metallwaren AG and Lemförder Metallwaren J. Ulderup AG & Co based in Lemförde, Northern Germany, has been part of ZF Friedrichshafen AG since 1984. The logo with the owl (as well as three tie rods originally) has hardly changed since the Lemförder Metallwaren-Gesellschaft mbH was founded in 1947 and is still a guarantee for quality. The idea to incorporate an owl arose from the name of the company founder, Ulderup – "Ule" is the Low German word for owl.

Since then, pride in precision has defined everything we have done and it continues to drive innovation in chassis technology to ensure safety on the road for decades to come.

- 1947 - The brand was founded and named after its hometown of Lemförde in Germany.

- 1949 - LEMFÖRDER began production of adhered rubber-to-metal elements, in which the rubber and metal components are vulcanized.

- 1950 - The company begins to provide tie rods to major brands such as Auto Union, Daimler- Benz, Klöckner- Humboldt-Deutz, Opel and Volkswagen.

- 1954 - LEMFÖRDER patents a ball joint consisting of a ball with a pin, which rests in a housing with bearing shells made of plastic, and is therefore maintenance free. The product range now includes tie rods and control rods, ball joints, wishbones and stabilizers.

- 1969 - Axle-guide bearing production begins

- 1975 - The 25 millionth LEMFÖRDER tie rod rolls off the production line.

- 1976 - LEMFÖRDER begins production of the first hydraulically damping engine mounts.

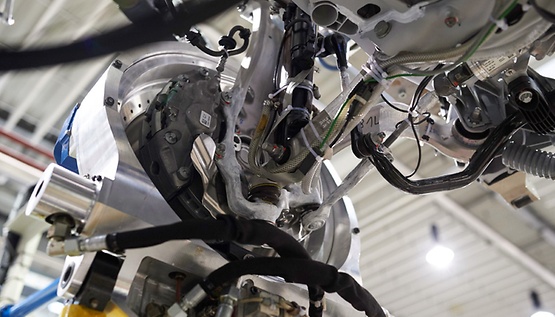

- 1986 - The first aluminium control arm for BMW goes into volume production.

- 1989 - LEMFÖRDER puts into operation the first multi- axial test bench to simulate real vehicle loads. This year also see the introduction of computer-assisted simulation processes.

- 1994 - LEMFÖRDER produces the first axle system for the BMW Z3.

- 2000 - Axle production for the BMW X5 begins.

- 2005 - The Sport Utility Convertible (SUC) is introduced, the result of a joint project between ZF LEMFÖRDER and Karmann.

- 2009 - LEMFÖRDER unveils an innovative lightweight axle prototype with composite leaf spring axles made of glass-fibre reinforced plastics at the IAA (Internationale Automobil-Ausstellung).

- 2011 - The LEMFÖRDER electric Twist Beam (eTB) prototype for driving compact cars by means of electric motors on the rear axle is first seen at the IAA.

- 2013 - Volume production of the Active Kinematics Control (AKC), an active tracking alignment system for the rear axle, begins.

- 2015 - LEMFÖRDER presents a modular rear axle system at the IAA. The LEMFÖRDER lightweight Sheet Metal integrated Control Arm (SMiCA) goes into volume production. LEMFÖRDER presents a lightweight hybrid stabilizer link made of glass-fibre reinforced plastics, polyamide and high-strength steel.

OE supplier with reputation

A reputation for perfection

As an OE supplier to vehicle manufacturers for decades, LEMFÖRDER has a reputation for developing products that are perfectly suited to the overall vehicle system. Through excellence in engineering, development and testing, bringing the benefits of generations of OE manufacturing expertise and a pioneering spirit to the aftermarket.

LEMFÖRDER is a dynamic brand, always innovating. We use state-of-the-art technology in our processes to ensure parts are engineered to perfection with regards to forces, materials, dimensions, durability and function.

LEMFÖRDER’s excellence in engineering has achieved advanced development of new lightweight composite parts for serial production across the world. Our production processes ensure parts are premium quality, with a longer life cycle, restoring the same comfort and safety to the vehicle that the driver enjoyed when it was brand new.

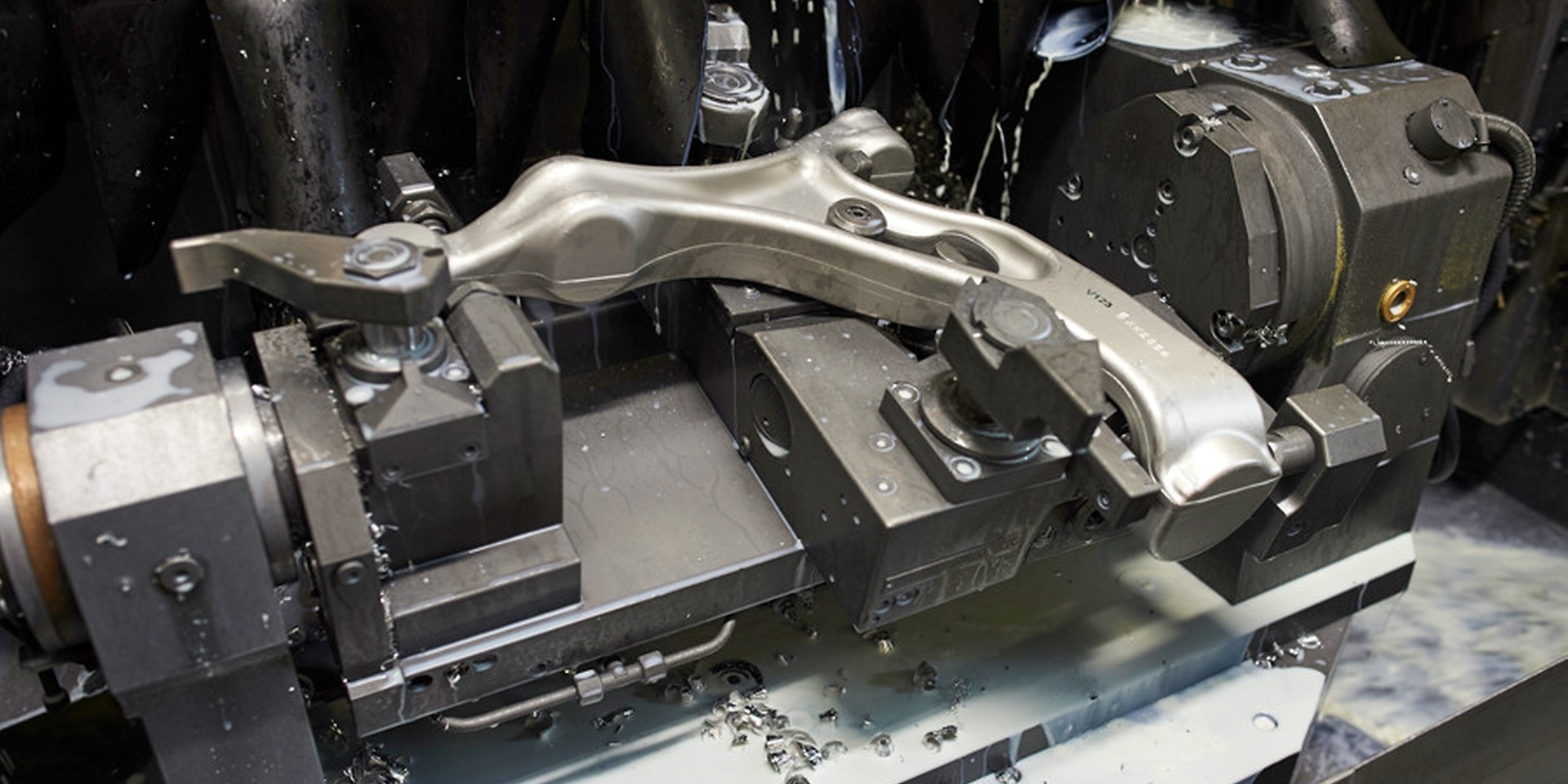

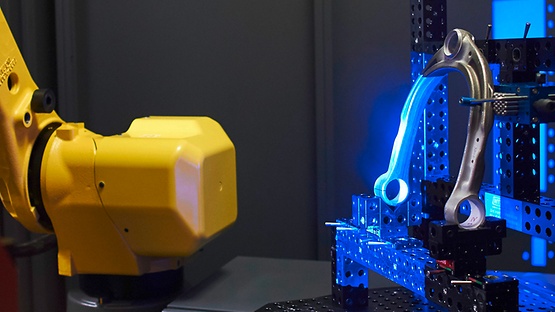

To achieve excellence in all we do, we examine every detail. LEMFÖRDER conducts tolerance tests to analyse the reaction of each material. We test all parts under all types of forces and road conditions, working directly with OE manufacturers to ensure each part is tested using machines that simulate extreme weather conditions and workloads.

LEMFÖRDER leads development processes in cooperation with OEMs. And because we provide OE parts to OEMs we must follow their tests. Every part fulfils OEM requirements, which means the independent aftermarket gets the best possible parts from LEMFÖRDER.

We constantly refine every part of every process to ensure that our parts are made with the most advanced production methods. LEMFÖRDER goes the extra mile, using specific technical processes that the competition does not match. Our fully automated production area in Diepolz (known as an elite plant) develops specific manufacturing processes, which are then rolled out and adopted in factories around the world.

And we go further. LEMFÖRDER conducts electronic and visual controls at every stage of the production process, while the highest possible audit of the part quality given only through Automotive industry – Certification according to TS 16949.

LEMFÖRDER conducts a ball joint tempering process that is unique to the brand. We are the only brand that performs ball joint contouring to ensure the hardening thickness is 100 % guaranteed and controlled by an ultrasonic analysis.

- LEMFÖRDER makes ball joints which are harder, smaller, lighter, stronger and safer, allowing more space for fitting, more strength for safety and less weight to improve fuel consumption.

- LEMFÖRDER pioneered ball joints that don’t need to be regreased – saving time, effort and cost for the installer.

- Only LEMFÖRDER can provide ball joints of such low elasticity that vehicles respond with greater agility, stability, driving dynamics and, above all, safety.

Discover our products

Quality from LEMFÖRDER

Quality Certification according to regulation (EU) No. 461/2010

Products sold by ZF Aftermarket under the LEMFÖRDER brand are spare parts within the meaning of Article 1 Figure (1) h) of Regulation (EU) No. 461/2010 dated May 27, 2010, and meet the criteria of Figures (19) and/or (20) of the supplementary guidelines on vertical restraints in agreements concerning the sale and servicing of automobiles and the sale of automobile replacement parts to the aforementioned regulation.

What does OE competence exactly mean?

Take a look at our development department and you will see!